In the earlier chapters we looked at the basic design of a pneumatic system and its most important elements:

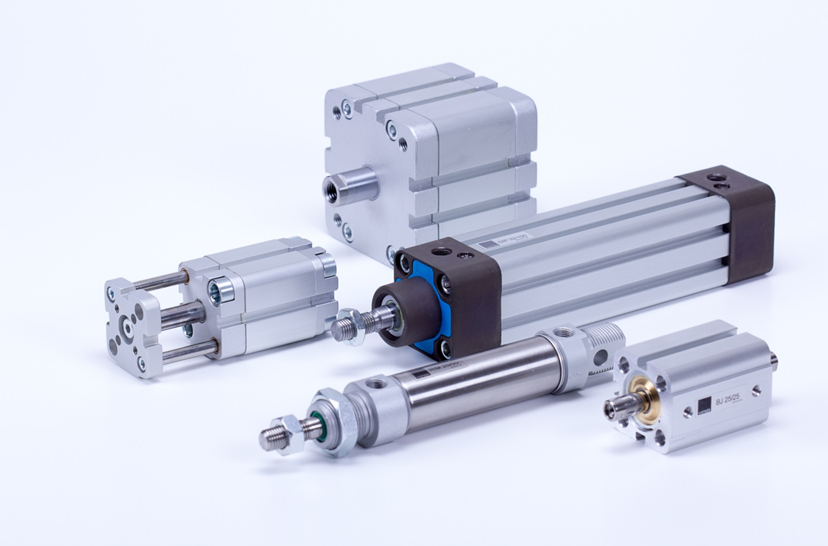

Cylinders are available in different types and follow different international standards. Besides the ones that follow standards there are also “non-standardized cylinders”. Especially before the standardization into DIN/ ISO norms 6431 and 6432, there were numerous cylinder-types offered by different manufacturers.

Common standard cylinders are:

- Mini cartridge cylinders

- Round cylinders | DIN ISO 6432

- Profile cylinders | ISO 15552 | VDMA 24562 | (old norm: DIN ISO 6431)

- Compact cylinders | ISO 21287 | UNITOP

- Short stroke cylinders

- Tie rod cylinders | ISO 15552

We will look at the following characteristics:

- Design

- Diameter and stroke

- Movement

- Number of positions

- ISO symbols

- Cushioning -> chapter 8

- Detection of cylinder position (magnetic) -> chapter 8

- Speed control -> chapter 8

- International Standards -> chapter 8

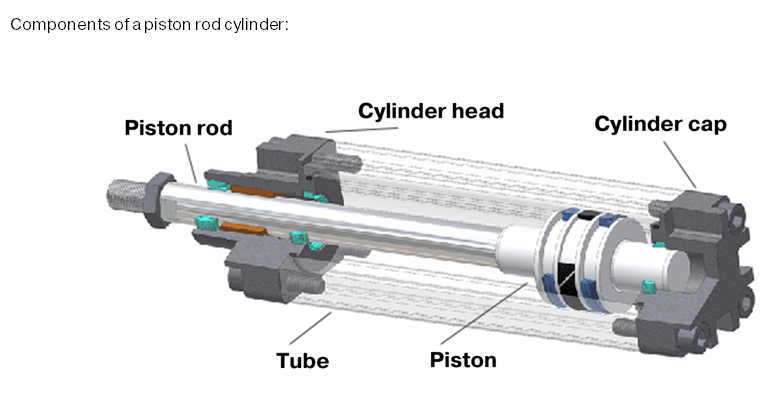

1. Design of a cylinder

Most of the cylinders with a piston rod contain the following parts: a tube that is closed on both ends with a cap and head. Inside the tube seen below a piston rod moves with a drive piston.

The movement of the piston is triggered by compressed air, controlled by a directional valve. The direction is defined by the chamber into which compressed air is allowed to flow inside the cylinder.

The force is transferred by the piston rod.

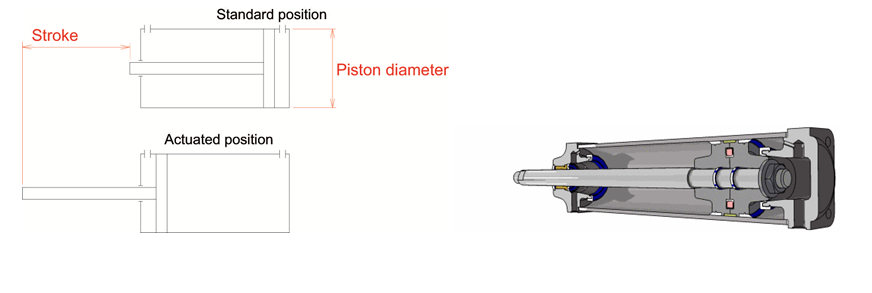

2. Diameter and stroke

Diameter and stroke are the most important attributes of a cylinder.

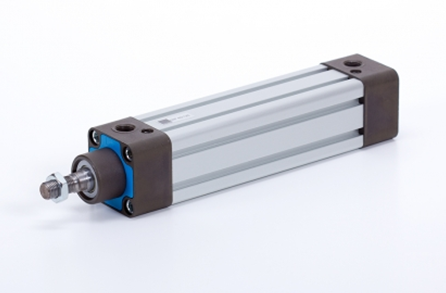

e.g. HAFNER Cylinder DIP: DIP 40/320

Type numbering system:

- DIP – type of cylinder / design

(DIP = ISO 15552 standard – double-acting cylinder – adjustable cushioning – magnetic piston)

- 40 – diameter of the piston [mm]

- 320 – stroke of the cylinder [mm]

The diameter is actually the diameter of the piston. The diameter of the cylinder defines its force relative to the air-pressure.

The stroke tells us how many millimetres the piston and therefore the piston rod can travel.

If the stroke is long, the forces on the bearing between head and piston rod are high. In order to avoid a defect we recommend to select a larger diameter (cylinders with larger piston diameters also offer larger piston rod diameters).

In case of very long strokes or radial forces we recommend the use of a guide unit.

The available diameters depend on, and are limited by, the type / standard. The availability of strokes on the other hand is less limited.

The maximum force generated by a cylinder depends on:

- Operating pressure

- Diameter of the piston

- Friction of the inner parts

As an example we calculate the force of a cylinder DIL 40/320 at 6 bar.

CAUTION! We can only hold the weight with this force, we cannot move it yet!

If we want to move a weight we have to (again) take gravity into consideration. Only then our cylinder is not only able to hold a weight but to perform work.

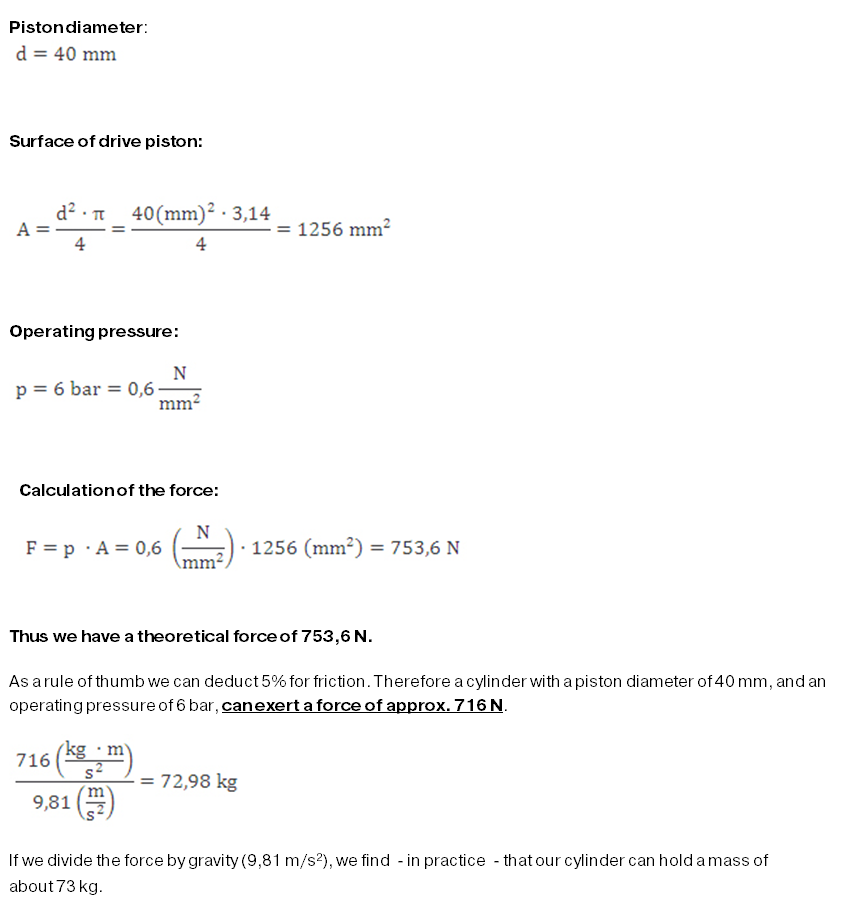

3. The Movement of a cylinder

We call the two end-positions of a cylinder positive / plus and negative / minus positions.

Therefore we also call the two chambers inside the cylinder the plus and the minus chamber.

The position where the piston rod is out of the cylinder the furthest possible is called the plus end-position. In order to reach it, the plus chamber needs to be inflated.

The minus end-position is positioned on the opposite side; the minus chamber needs to be inflated.

The cylinder cannot reach an end-position if the opposite chamber is not fully exhausted!

4. Stable positions of a cylinder

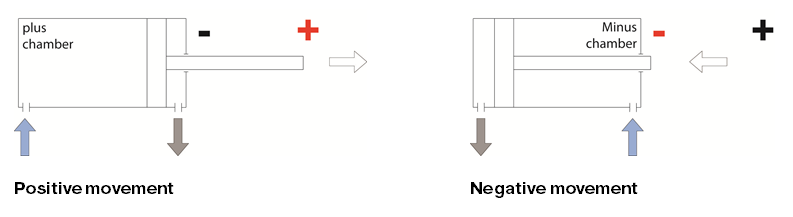

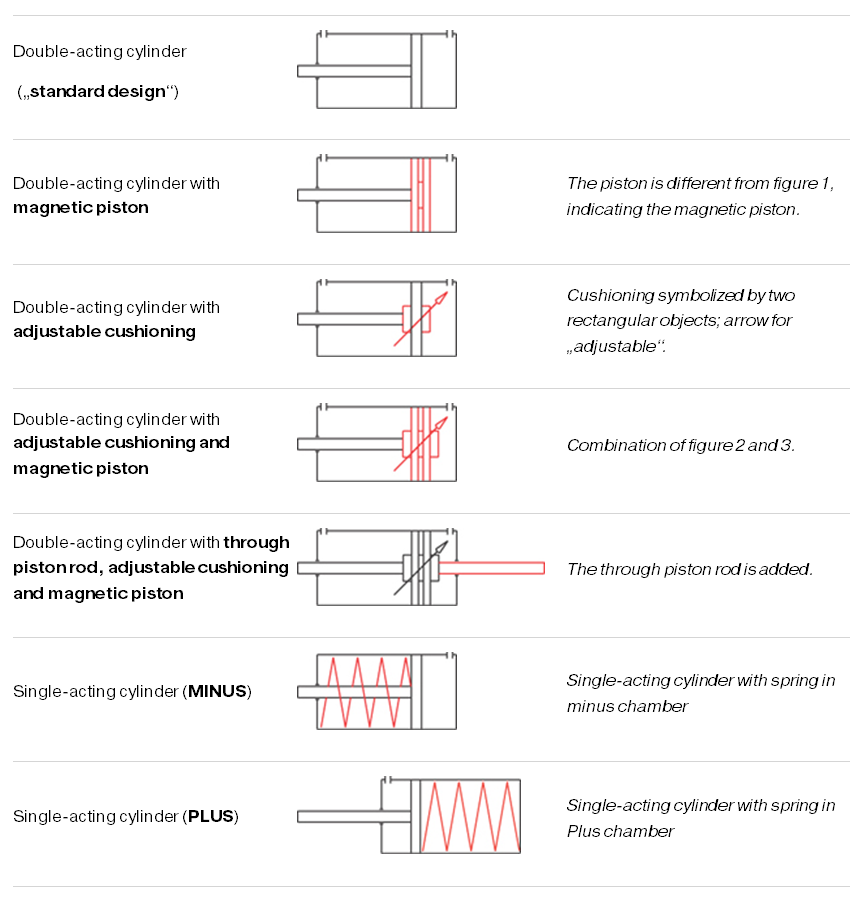

We distinguish between single-acting and double-acting cylinders.

In single-acting cylinders only one chamber is inflated with compressed air. Therefore work is performed only in one direction by compressed air. For the movement into the opposite direction a mechanic spring is the source of energy. The stroke is limited by the length of the spring. In general single-acting cylinders offer a relatively short stroke.

Two different types of single-acting cylinders are available:

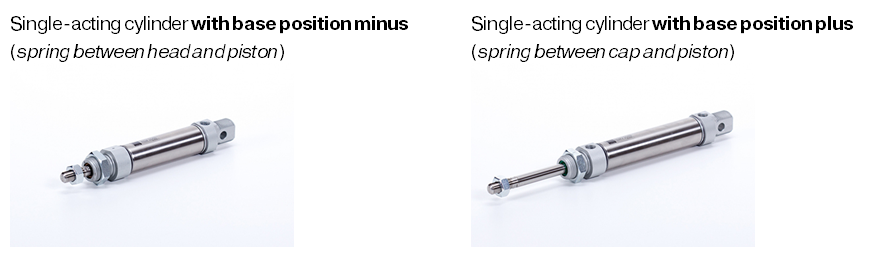

Double-acting cylinders are driven in both directions by compressed air. They are always used when work has to be performed in both directions or when the required stroke is longer than the available springs.

There are different designs for different applications:

5. ISO symbols

In order to distinguish between cylinders, there are also well defined ISO symbols and schemes indicating their different functions. These do not however indicate their size, diameter, stroke, ISO-standard etc.

We introduced the following expressions:

- Cushioning

- Magnetic piston

Their explanation will follow in the next chapter. Just to give you a short insight:

- The adjustable cushioning slows the cylinder down when the piston is entering either head or cap. The idea is to avoid a hard shock when the piston hits these elements.

- The magnetic piston is required if we want to check the positon of the piston with a REED-switch. The switch is added onto the outside of the cylinder. When the piston travels by, the switch sends a signal.