Review of previous chapters

In the earlier chapters we introduced you to the most important characteristics of directional valves.

We have summarized them below:

Categorizing control valves by the following criteria (chapter 3):

- Basic design

(spool valve, poopet valve) - Actuation

(mechanically, manually, pneumatically or electrically actuated valves) - Number of positions

(2-, 3-, 4-, 5-way) - Number of ports (in combination with positions)

(2/2-way, 3/2-way, 5/2-way, 5/3-way, …) - Normal position

(for 2/2-and 3/2-way valves: normally closed or open, for 5/3-way valves: center closed, exhausted, pressurized)

By design (chapter 4) we have to distinguish between poppet and spool valves. It is important to understand the difference in order to select the right valve for any application.

- 2/2- or 3/2-way electrically and directly actuated poppet valves: directly controlled by the plunger of the solenoid system.

- 3- or 5-way electrically actuated spool valves: controlled by an additional pilot-valve

Introduction to directional valves (chapter 5):

- ISO symbols and their meaning when it comes to function and positions

- Numbering of their ports

Explanation of the Hafner type numbering system

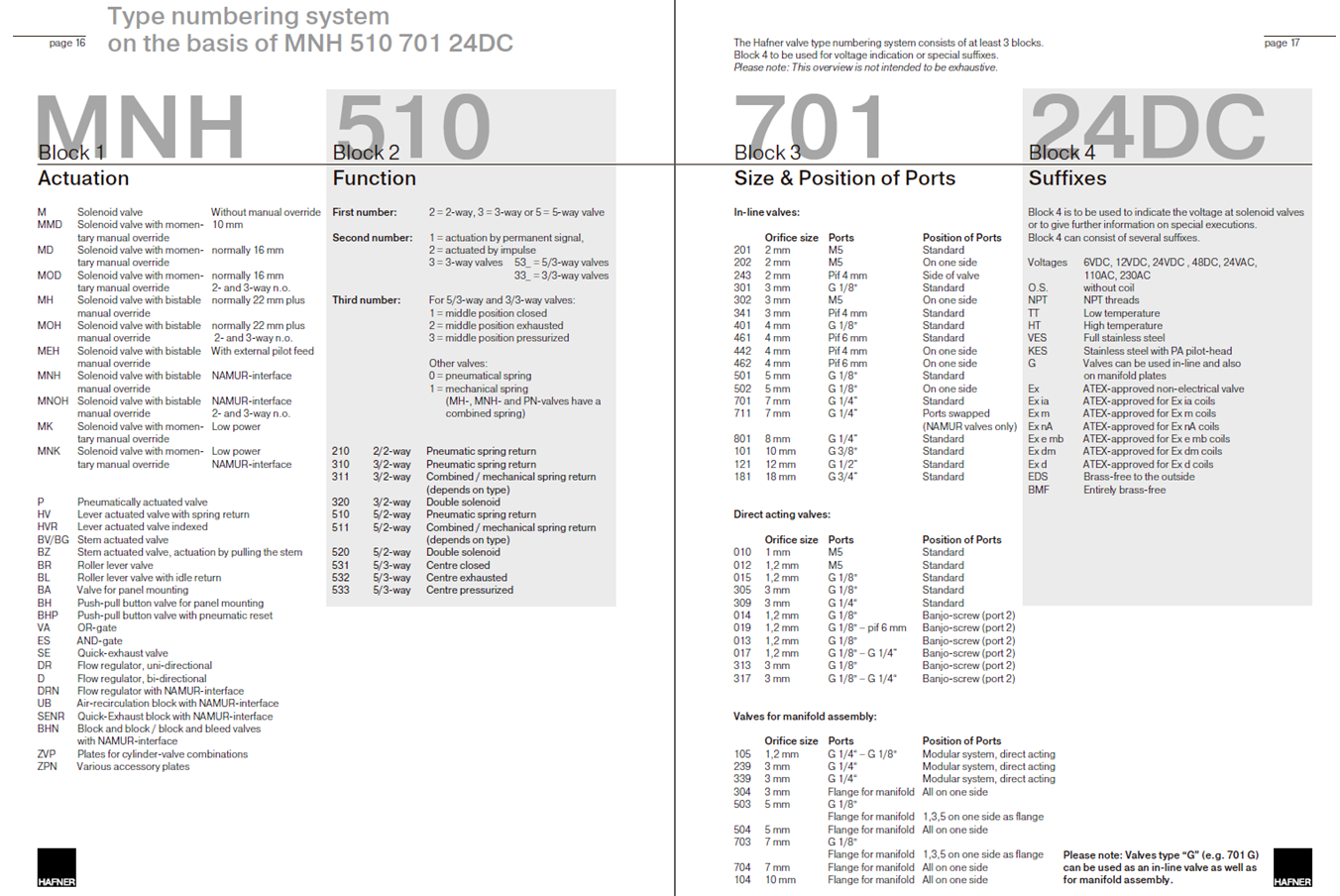

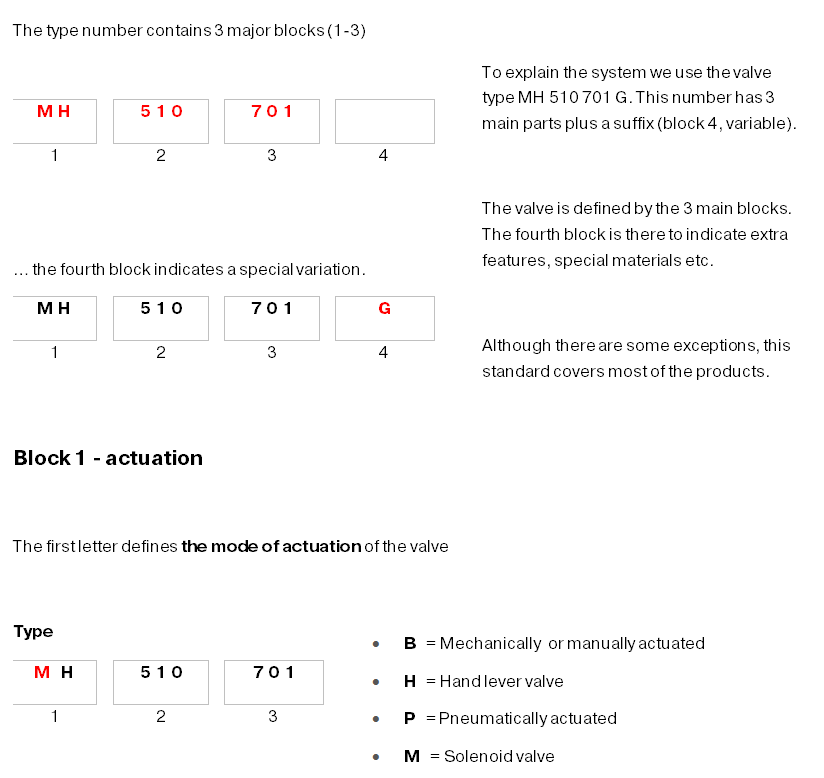

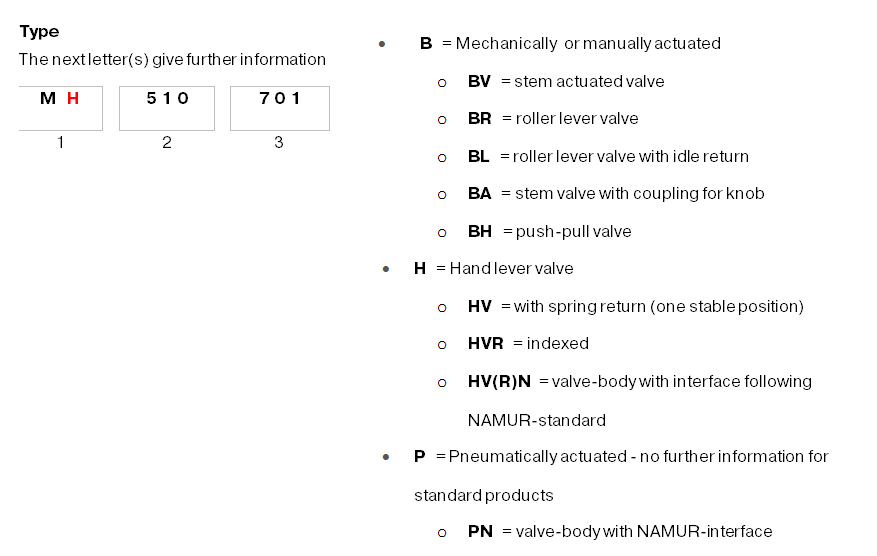

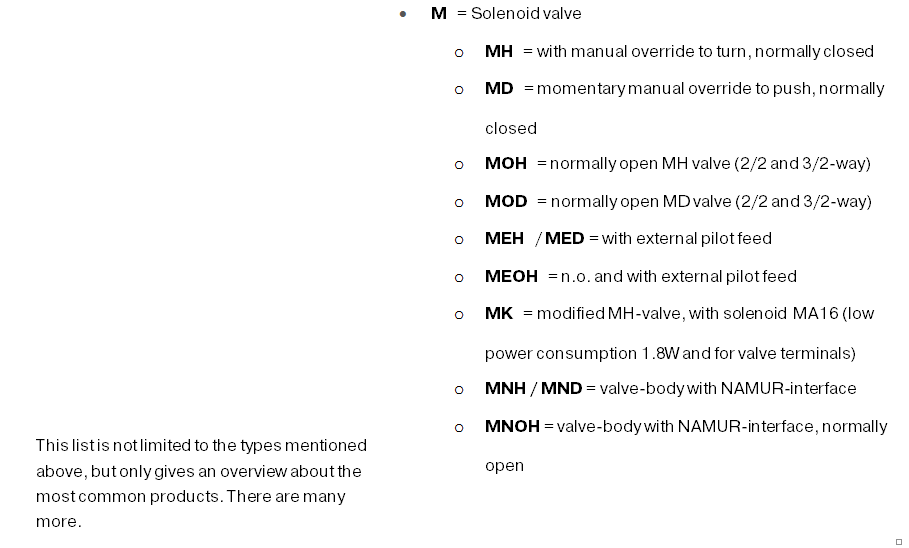

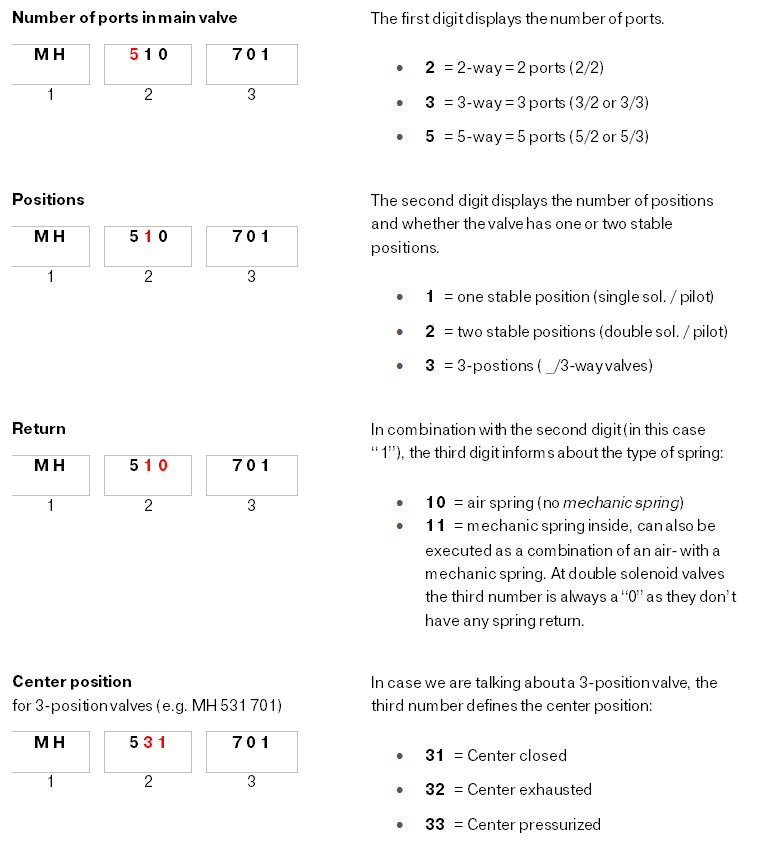

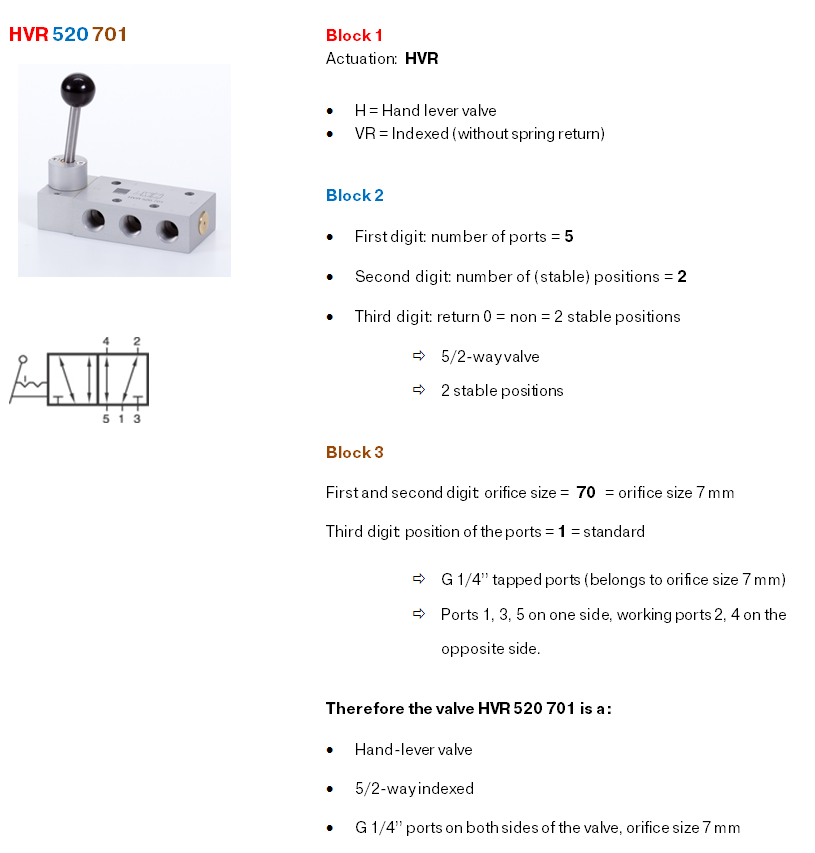

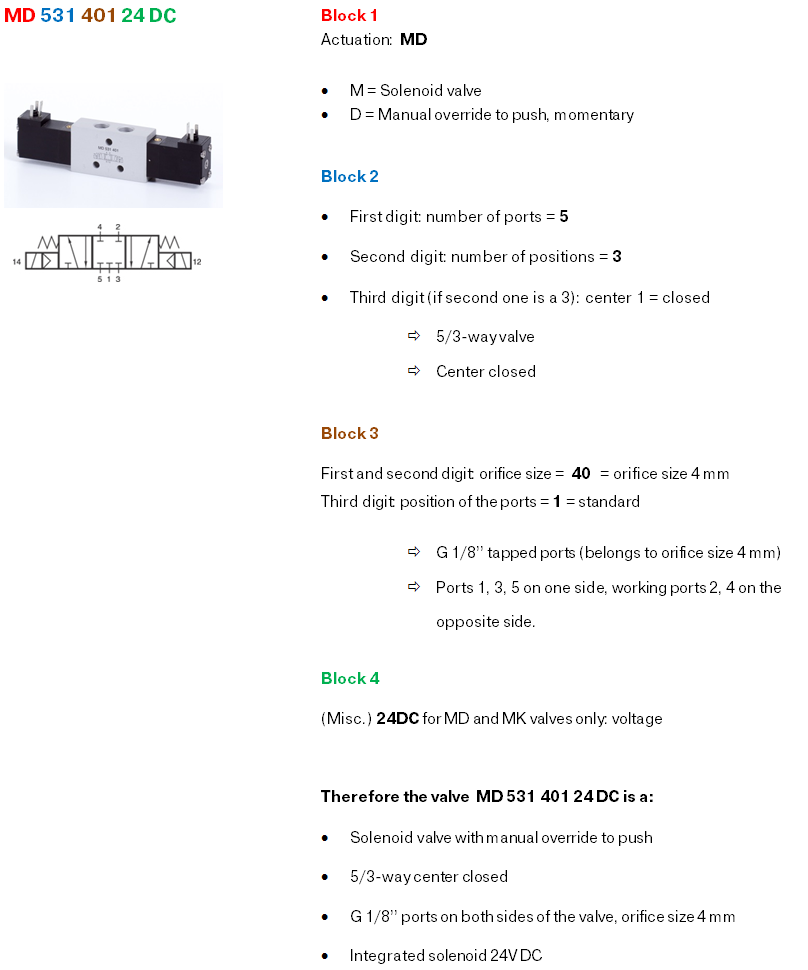

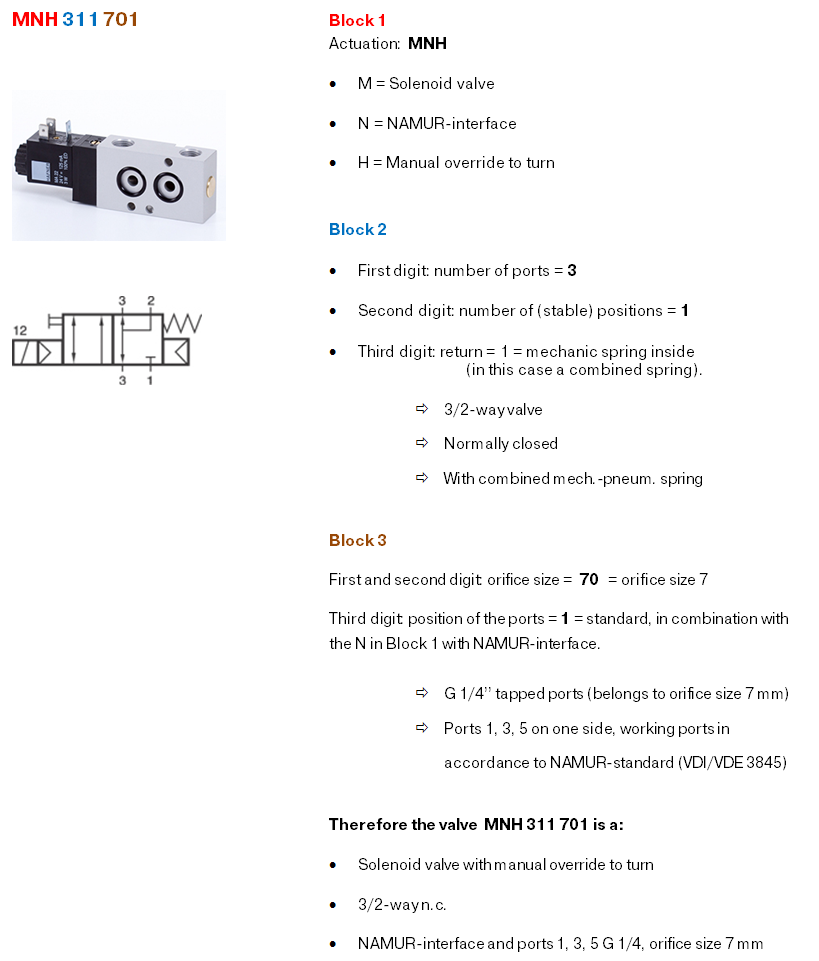

The HAFNER type numbers are a combination of letters and numbers, which carry further meaning. The most important characteristics of the valves are to be found in the type number.

Block 2

The second block contains information about the number of ports, the number of stable positions and the type of spring.

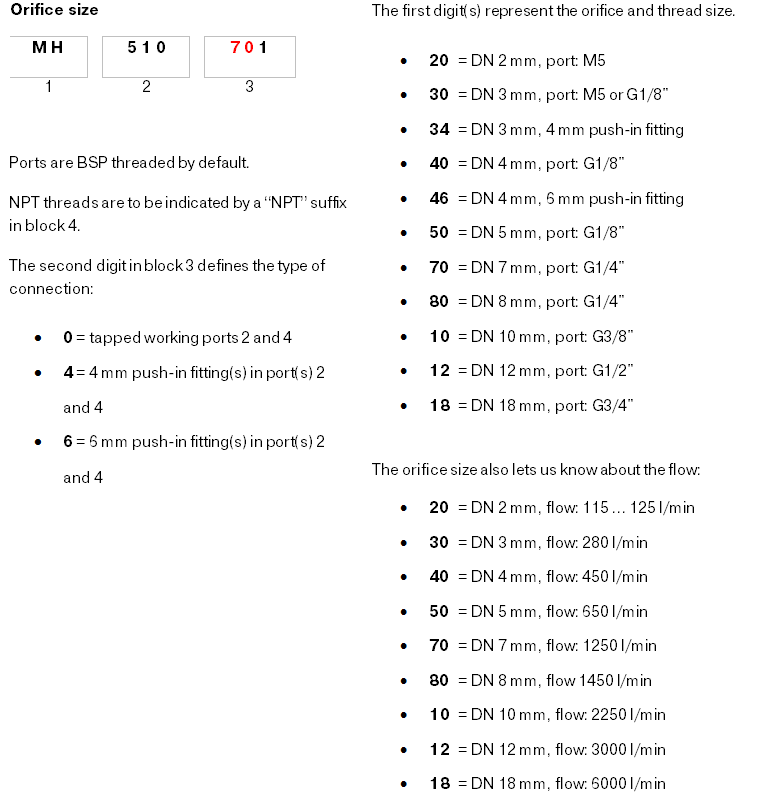

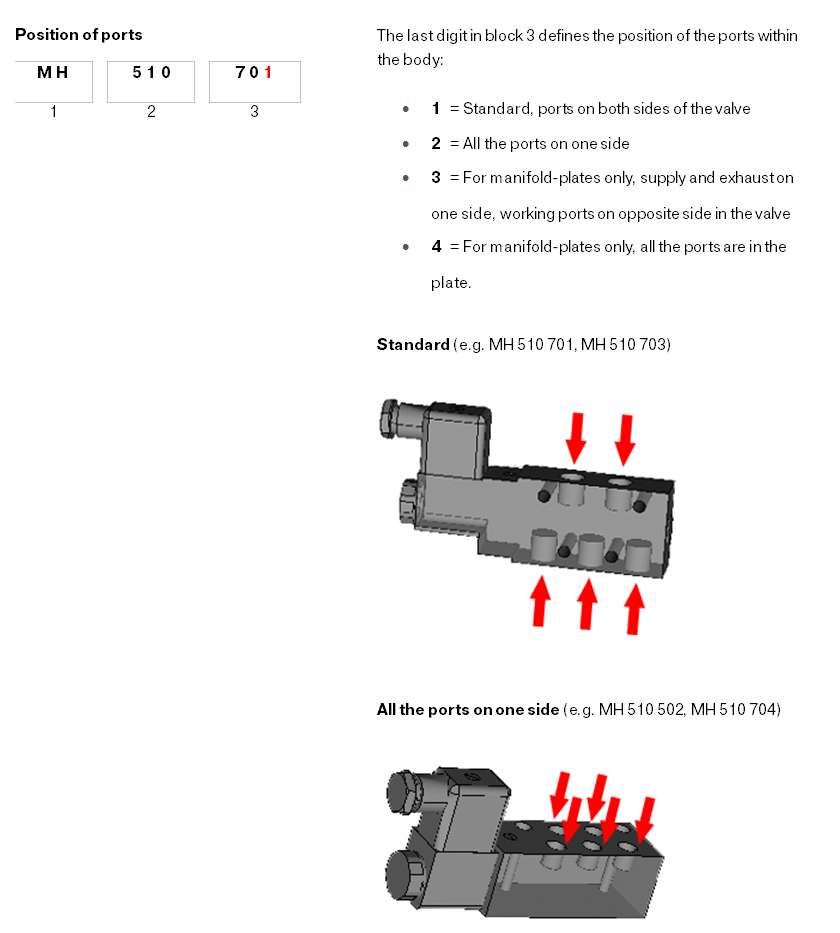

Block 3

Block 3 contains information about orifice size and ports.

You can get more information about flow from the catalogue.

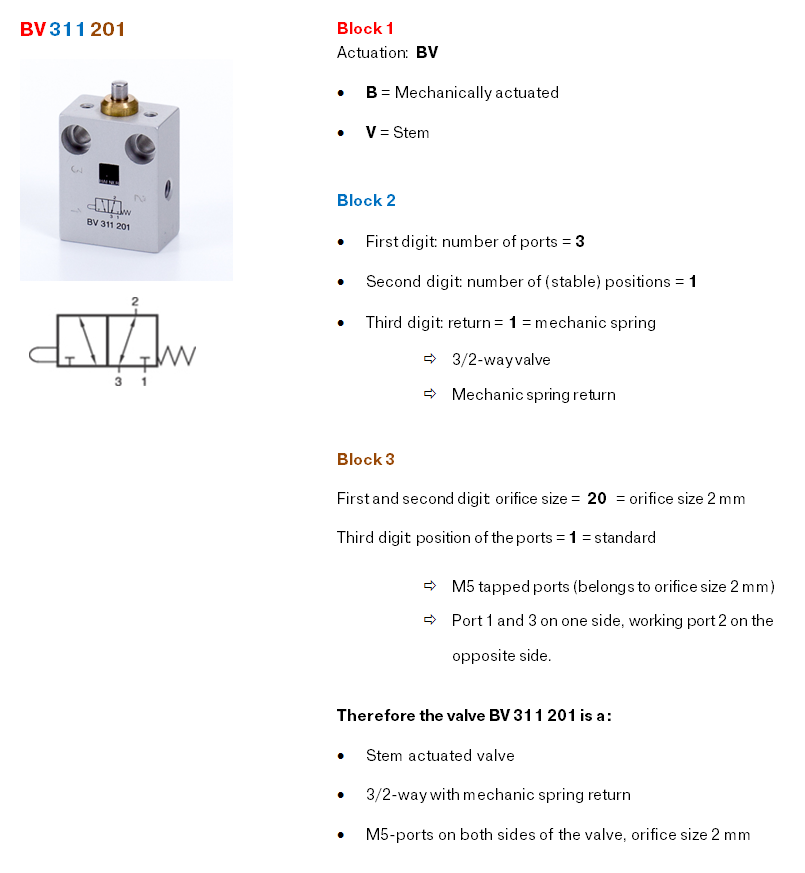

Below we explain some exemplary type numbers based on catalogue items:

As you can see the HAFNER type numbering system is following a standard that allows you to understand what type of valve is in use or required whenever those numbers are mentioned.

An overview about the structure of the Hafner type numbers can also be found on page 16 and 17 in the valve catalogue 2016: