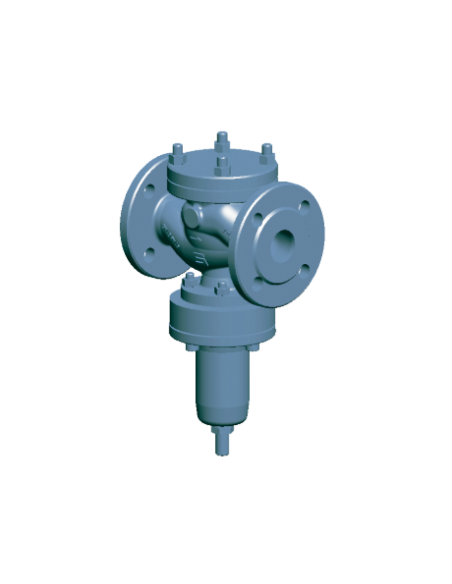

Ο Μειωτής πίεσης REA20 της Miyawaki είναι ένας αξιόπιστος και αποδοτικός μηχανισμός που χρησιμοποιείται για τη ρύθμιση και τη μείωση της πίεσης σε συστήματα υδραυλικών εγκαταστάσεων. Σχεδιασμένος για να προσφέρει σταθερή απόδοση, ο REA20 εξασφαλίζει την ομαλή λειτουργία του συστήματος, προστατεύοντας τα εξαρτήματα από υπερβολική πίεση. Κατασκευασμένος με υψηλής ποιότητας υλικά, προσφέρει αντοχή και μακροχρόνια χρήση, καθιστώντας τον ιδανική επιλογή για διάφορες εφαρμογές.