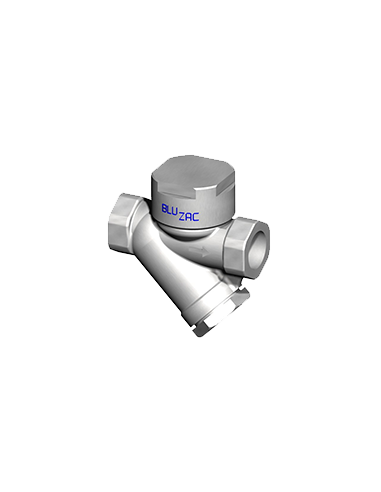

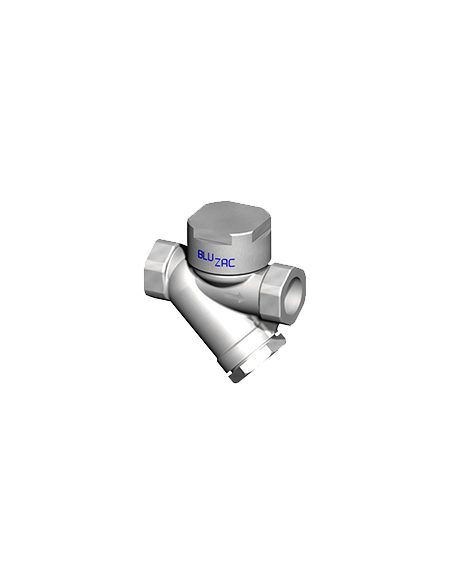

The thermostatic capsule type of steam trap is created for standard applications, designed for standards customer’s requirements, it’s obtained from a machined forged billet.

Steam traps suitable for high pressures and capacities, usable for all applications.

How it works:

- The membrane inside the capsule, which is attached to the housing, is raised.

- Start-up: when the condensate begins to circulate, the capsule is prevented from reacting to the low temperature, keeping the membrane and the shutter in the open position.

- As the system heats up, the condensate reduces and steam begins to arrive, heating the fluid inside the capsule and expanding its volume. The thrust this generates presses the shutter onto the housing, blocking the flow and trapping the steam.

- As more condensate accumulates, the fluid inside the capsule cools, making the membrane contract, opening the housing and discharging the excess condensate.