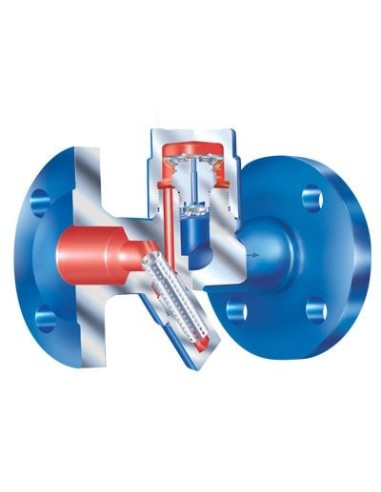

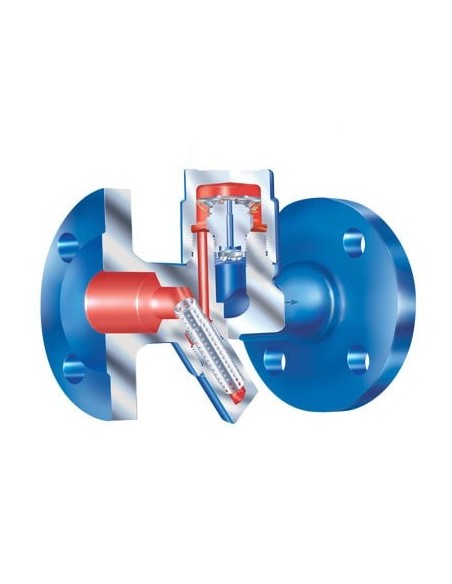

Key Features of CONA® M Thermostatic Steam Traps:

- Thermostatic Steam Trap Design:

- Suitable for discharging condensate from systems operating at various temperatures.

- Automatic air-venting during start-up and operation.

- Robust, water hammer-proof capsules for durability.

- Non-return protection to avoid reverse flow (not available with controller R5).

- Designed to handle sub-cooled condensate (with a range of temperature adjustments).

- Inside or outside strainer options depending on model.

Types of Connections:

- Flanges (DIN EN 1092-2)

- Union with butt weld ends

- Screwed sockets (Rp thread or NPT thread)

- Socket weld ends

- Compression ring connection (for PN40)

- Clamp connection (for PN16)

Capsule Options:

- Capsule No. 1: For condensate discharge at boiling temperature (applicable up to 5 bar inlet pressure).

- Capsule No. 2: For condensate sub-cooling around 10K (Standard).

- Capsule No. 3: For condensate sub-cooling around 30K.

- Capsule No. 4: For condensate sub-cooling around 40K, especially for tracing systems with low and medium-pressure steam.

Models and Performance:

- CONA®M 610 (PN16): Handles operating pressure up to 12.8 barg and inlet temperatures up to 200°C.

- CONA®M 610/612 (PN40): Designed for higher pressures (up to 22 barg) and temperatures up to 385°C.

- CONA®M 611/613 (PN40): A higher capacity version for steam traps requiring large flow rates.

- CONA®M 616 (PN40): A high-capacity model with multi-capsules for very high flow rates, suitable for up to 32 barg pressure.

Material Options:

- Grey Cast Iron (EN-JL1040)

- Forged Steel (P250 GH)

- Stainless Steel (1.4301, 1.4541)

- High-Temperature Steel (16Mo3)

Applications:

These thermostatic steam traps are commonly used for:

- Condensate discharge in industrial steam systems.

- Steam tracing and heating applications.

- Systems requiring high sensitivity and precise control over condensate drainage.