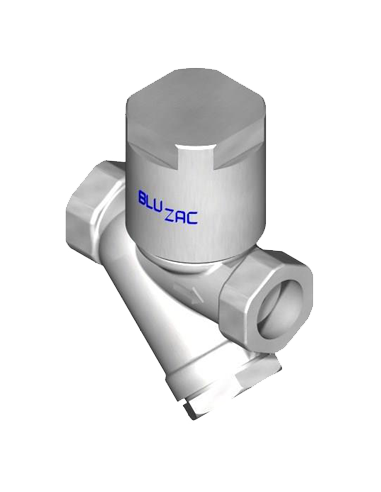

The thermostatic bimetallic pack type of steam trap is created for standard applications, designed for standards customer’s requirements, it’s obtained from a machined forged billet.

How it works:

- The bimetallic pack inside the capsule attached to the housing is raised.

- Start-up: when the condensate begins to circulate, the bimetal is prevented from reacting to the low temperature, keeping the shutter in the open position.

- As the system heats up, the condensate reduces and steam begins to arrive, heating the bimetal, which reacts by bending. The combined force generated by the pack of bimetallic discs creates a movement on the shutter, lifting it until it comes into contact with the housing.

- As the condensate accumulates, the bimetal cools, contracting and releasing the shutter, which in turn frees the flow.

| SIZES |

|---|

| from ¼” to 2.1/2” |

| CONNECTIONS | ||

|---|---|---|

| Buttweld | BW | ANSI B16.25 |

| Flanged | FLG | ANSI B16.5 |

| Socket Welding |

SW | ANSI B16.11 |

| Screwed | NPT BSP |

ANSI B1.20.1 ANSI BS21 |