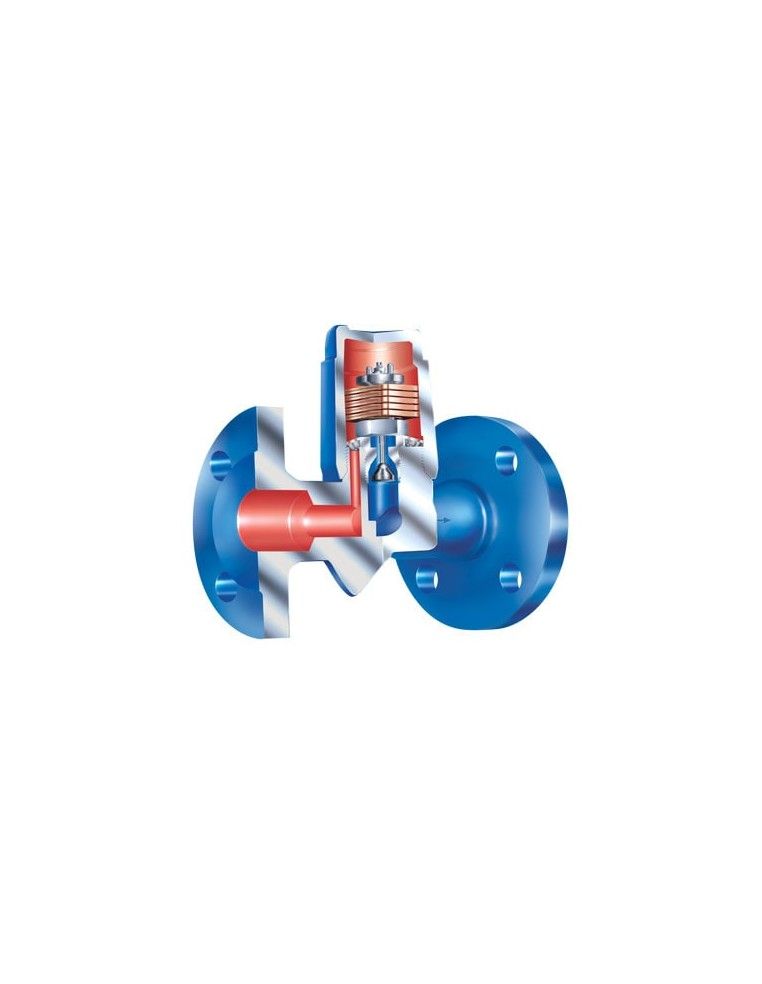

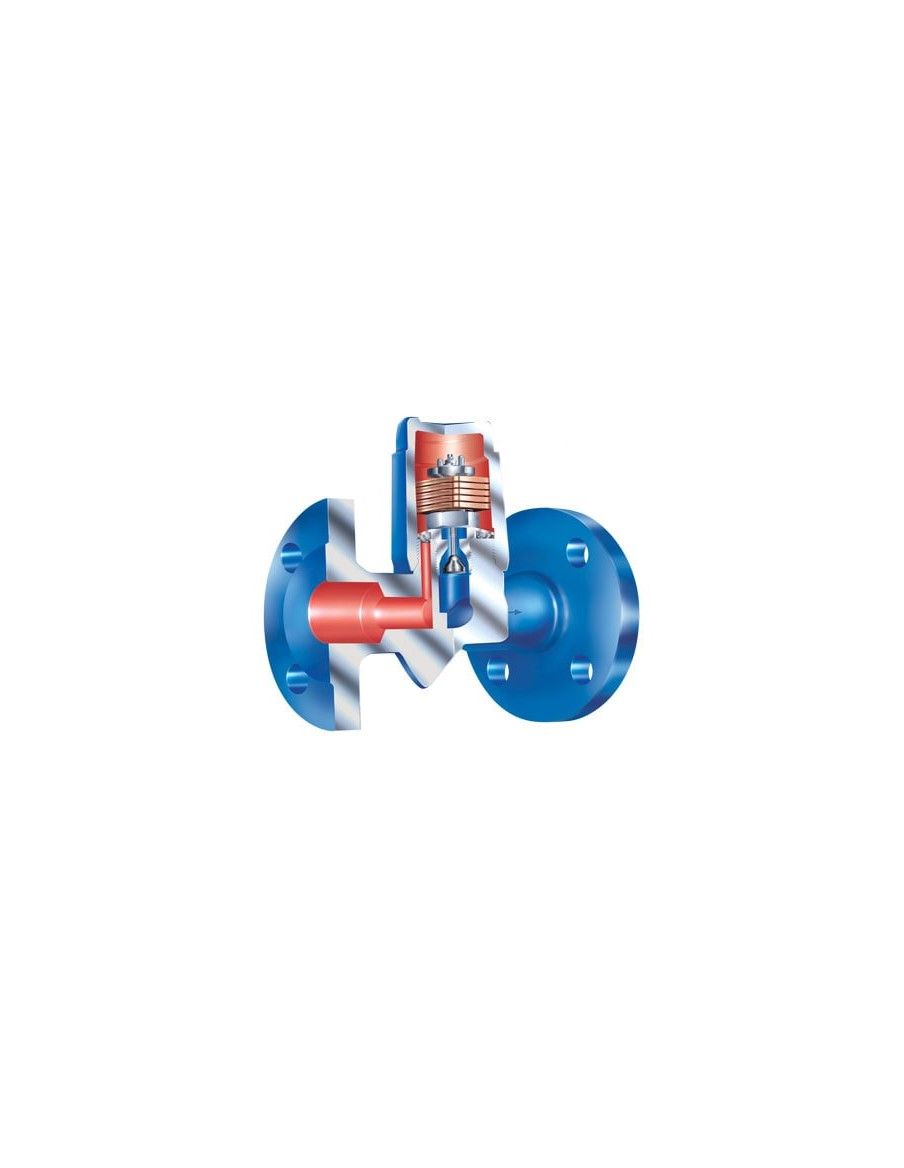

Key Features of CONA® B Bimetallic Steam Traps:

- Thermostatic Steam Trap: Designed for discharging condensate from steam systems, with automatic air venting during startup and operation.

- Robust and Resistant: The bimetallic controller is resistant to water hammer and is corrosion-proof.

- Non-return Protection: Ensures there is no reverse flow in the system.

- Adjustable Subcooling: The condensate subcooling can be continuously adjusted based on operational needs.

- Installation: The steam trap can be installed in any position except with the cover or screwed cap facing downward.

- Strainer Options: The steam trap comes with an inside strainer (Fig. 600) or outside strainer (Fig. 601).

Pressure Ratings & Materials:

- PN16: Made from Grey Cast Iron (EN-JL1040, EN-GJL-250), with connections via flanges or union with butt weld ends. Operating pressure up to 12.8 barg and inlet temperature up to 200°C.

- PN40: Available in Forged Steel, High-Temperature Steel, and Stainless Steel (1.4541, 16Mo3). The pressure rating is up to 32 bar, and the temperature can reach 450°C for higher-end versions.

- PN63 / PN100: High-Temperature Steel with operating pressure up to 46 bar and inlet temperature up to 450°C.

- High Pressure (PN160 / PN250): Available for up to 154 barg pressure and 550°C temperature.

- PN320 / PN400 / PN630: Highest pressure ratings for special high-temperature applications (up to 320 barg and 600°C).

Models & Performance:

- CONA® B 600: Available in different sizes for DN15 to DN50 with various materials and connection types.

- PN160 to PN400: Specifically designed for high-pressure applications, capable of handling extreme operating conditions, with different materials available based on temperature and pressure needs.

Types of Connections:

- Flanges (DIN EN 1092-1)

- Screwed Sockets (Rp thread, NPT thread)

- Socket Weld Ends (DIN EN 12760)

- Butt Weld Ends (Weld preparation as per EN ISO 9692)

Controller Types:

- Controller R13: Suitable for pressures up to 13 bar.

- Controller R22: Suitable for pressures up to 22 bar.

- Controller R32: Suitable for pressures up to 32 bar.

- Controller R56, R90, R130, R150, R270: For high-pressure models, with varying maximum inlet pressures up to 320 bar.