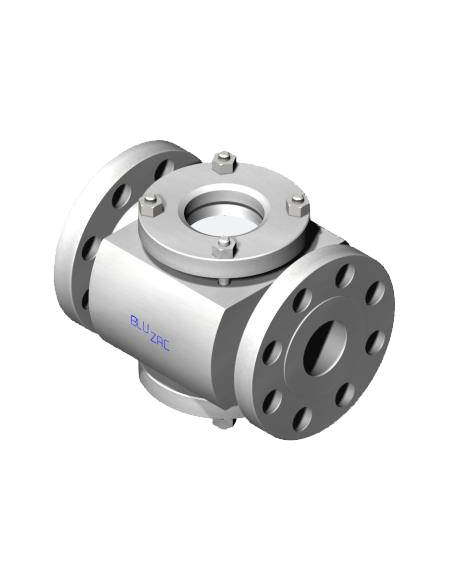

Sight glass indicators are pieces of equipment used to observe the flow of a fluid in a pipe.

Comprising a flanged body, completely machined as a single piece, with two pieces of glass held in place by two flanges, the sight glass indicator may contain a floating or static flow indicator, which allows for instant, safe monitoring of flow inside the pipe.

On request, special versions for pressures and temperatures specified by the customer can be produced for use in a wide variety of industrial applications.

| SIZES |

|---|

| from 3/8” to 4” |

| CONNECTIONS | ||

|---|---|---|

| Buttweld | BW | ANSI B16.25 |

| Flanged | FLG | ANSI B16.5 |