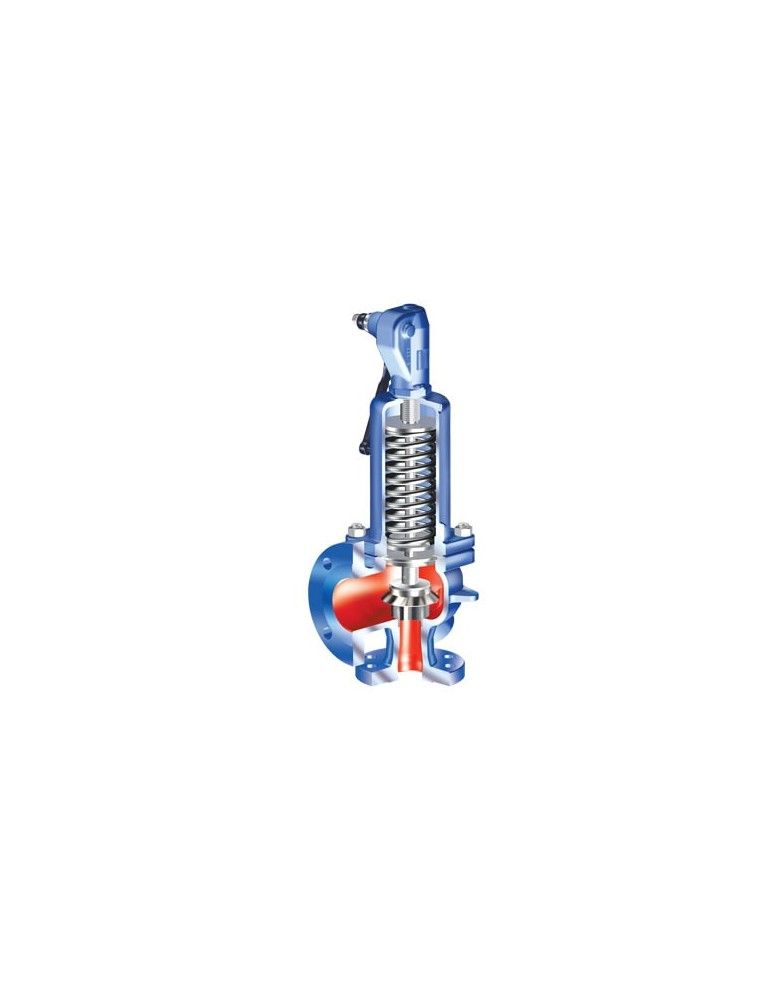

ARI-SAFE-SN ANSI (Semi-Nozzle) Safety Valve Features:

- Approval & Certification:

- Type-test approved according to ASME Code Section VIII-Division 1.

- UV-stamp and NB-stamp for national board certification.

- Spring-loaded design: Direct-loaded with spring.

- Precision Engineering: Wear-resistant seat/disc and precision disc alignment and guide for reliable operation.

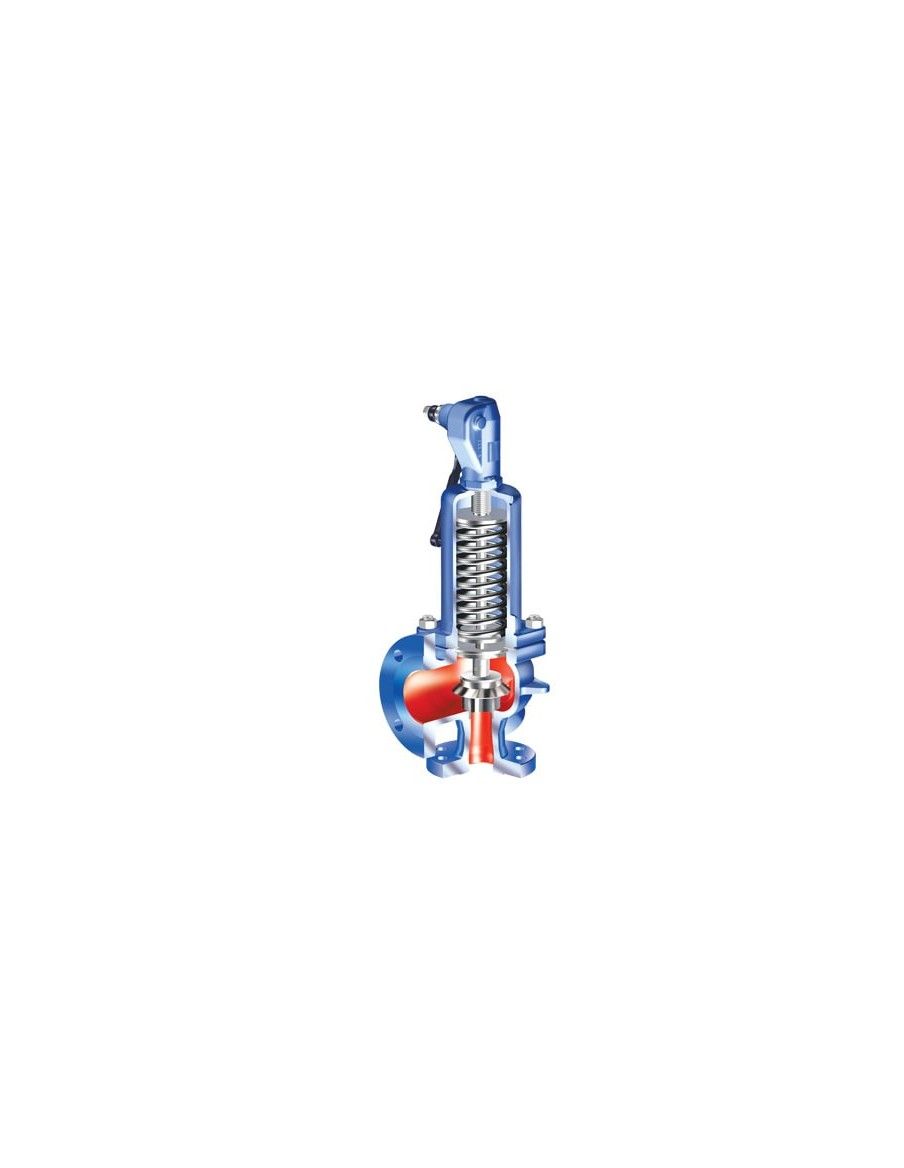

- Material Options:

- Standard SA216WCB (carbon steel) and SA351CF8M (stainless steel) for the body.

- Stainless steel bellows or EPDM bellows options for sealing.

- Operating Temperature: From -75°F to 800°F depending on the material.

Valve Models and Sizes:

- Fig. 901 / 902 / 911 / 912 models available, with various bonnet designs (closed, open, or gastight).

- Flange Type: ANSI 150/300 (ASME B16.5 standard).

- Nominal Pressure: Available in ANSI 150, ANSI 300 ratings.

- Nominal Diameter: From 1" x 2" to 6" x 10".

Application:

- Steam, gas, and liquid media: Used for pressure relief in systems handling gases, vapors, and liquids.

- Back Pressure Handling: Can handle built-up back pressure (up to 10% of set pressure, higher on request). No back pressure is allowed on request.

- Set Pressure: Available in various set pressure ranges, with specific capacities for different applications, including saturated steam, air, and water.

Sizing & Capacity:

- Sizing calculations are based on API 520 (ASME VIII) for mass flow (gas), volume flow (liquid), and set pressure (psig).

- Capacity Data:

- For saturated steam at set pressures between 15-493 psig, with discharge capacities ranging from 510 lb/hr for smaller sizes to 14460 lb/hr for larger sizes.

- For air, similar data ranges from 182 SCFM to 60421 SCFM depending on the size and set pressure.

- Water capacity ranges from 61 gal/min at 15 psig to 52344 gal/min at higher pressures.

Spring Ranges:

- The valve is available with various spring ranges for different set pressure requirements, with standard ranges from 15-22 psig to 250 psig and higher options for specific applications.

Dimensions:

- The center-to-face dimensions are according to API 526, and the flange dimensions follow ANSI B16.5 standards.

- The valve dimensions and weights vary according to the nominal diameter, with sizes ranging from 1"x2" up to 6"x10".

Approvals & Additional Features:

- Soft-sealing disc options are available for different sealing materials, such as EPDM, Viton, or Neoprene.

- Stainless steel bellows for back pressure compensation (only for closed versions).

- Special design options include proximity switches, test gag, rupture disc, and heating jackets for specific applications.

MyValve® Sizing Program:

- MyValve® is a software tool for sizing valves and components based on given parameters like capacity, pressure, and medium. It provides direct access to spare parts drawings, product data, and more, with the ability to calculate the right valve size based on your needs.