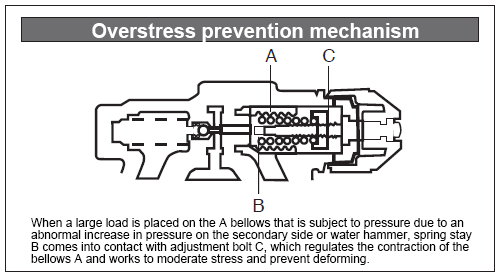

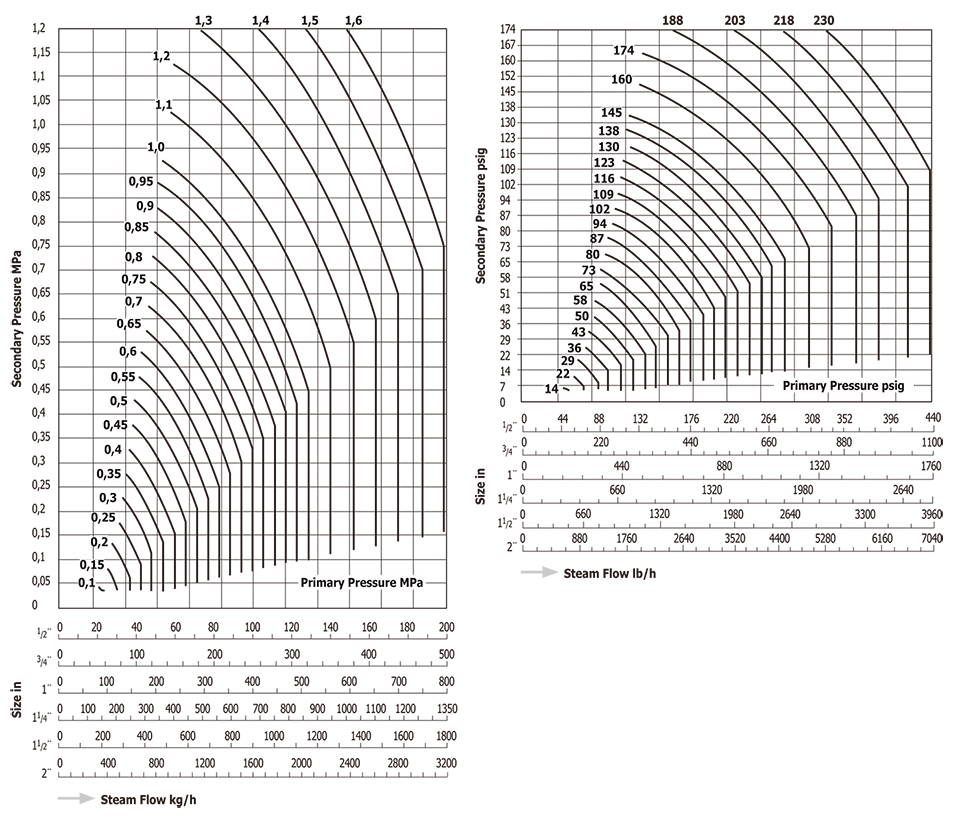

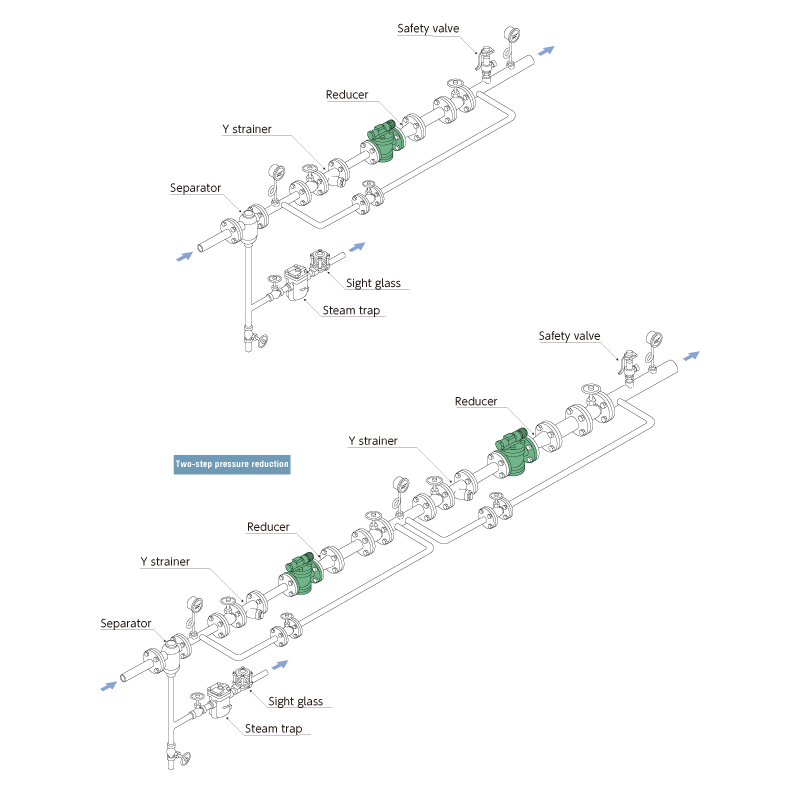

The RE10N is a pilot-operated pressure reducing valve designed specifically for steam applications, manufactured by Miyawaki. This valve is engineered to provide precise control and stable downstream pressure, ensuring efficient steam management in various industrial processes. Its pilot-operated mechanism allows for accurate pressure adjustments and responsiveness to changes in demand, making it ideal for maintaining optimal performance in steam systems. The RE10N is known for its durability, reliability, and ease of maintenance, making it a preferred choice for industries requiring consistent steam pressure regulation.