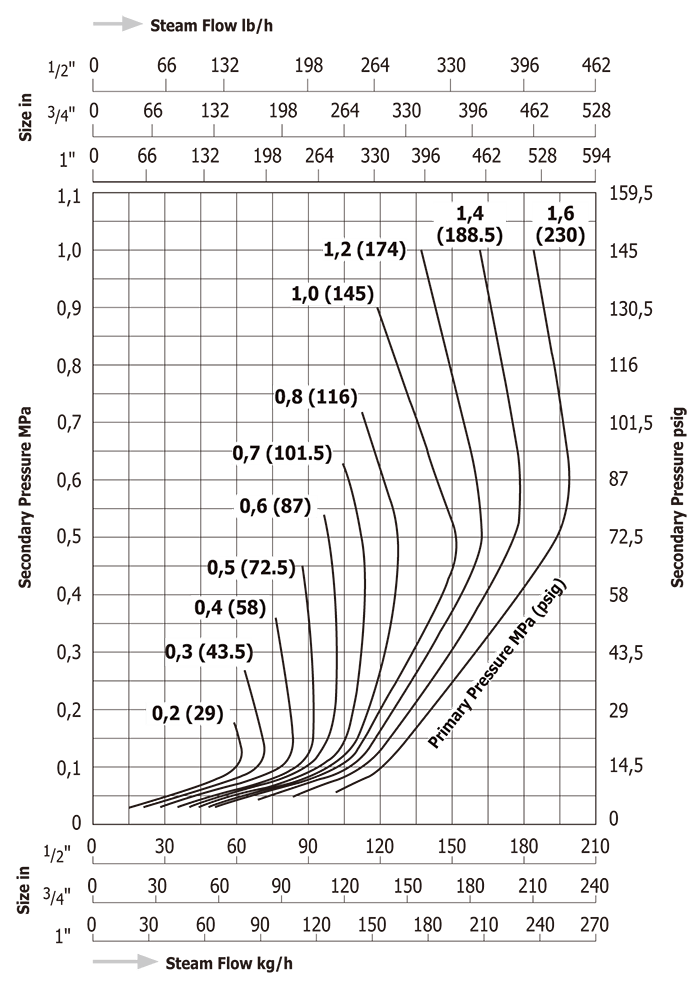

The Pressure Reducing Valve - Direct Acting for Steam REC1 by Miyawaki is a high-performance valve designed to regulate and reduce steam pressure in various industrial applications. This valve operates on a direct-acting mechanism, ensuring precise control and reliability. It is engineered to maintain a consistent downstream pressure despite fluctuations in upstream pressure or flow rates. The REC1 model is known for its robust construction, ease of installation, and low maintenance requirements, making it an ideal choice for efficient steam management in systems requiring stable pressure control.