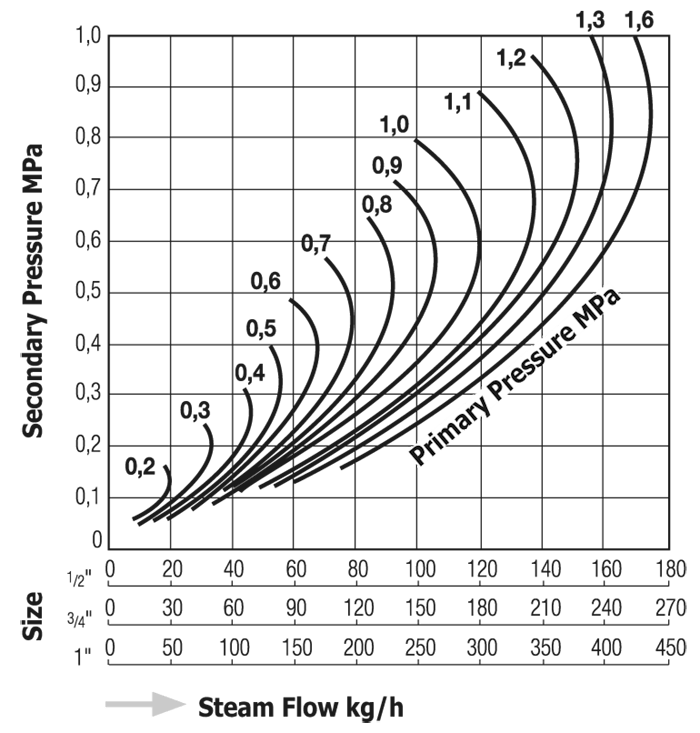

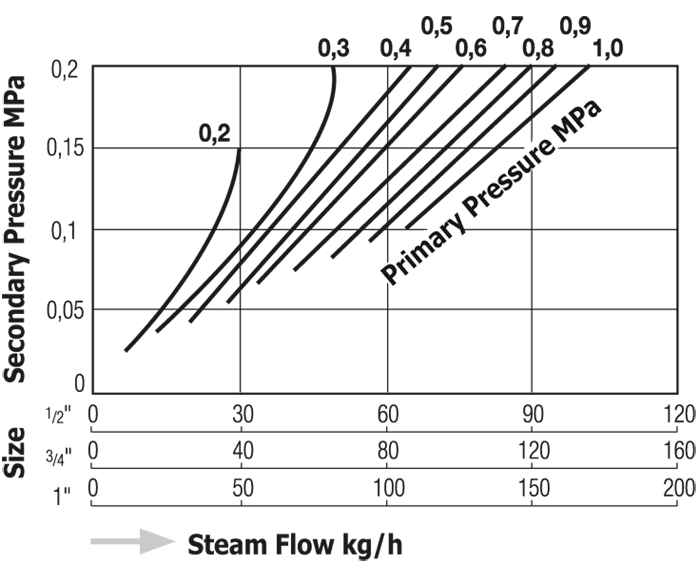

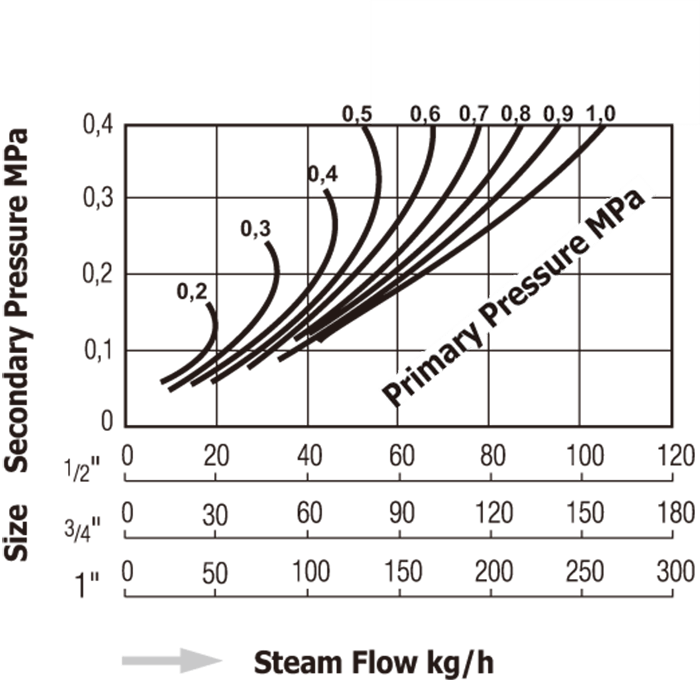

Pressure reducing valves (PRV) are designed for regulating the downstream pressure and maintaining it within certain acceptable limits.

Ideally, a PRV should provide a constant downstream pressure while delivering the required flow, i.e.

The PRV automatically adjusts the steam flow to meet the downstream system demand.

Depending on the model, MIYAWAKI’s pressure reducing valves are designed for steam, air, gases and liquids.

Operating principle

Changes in downstream pressure are sensed by the bellows, which expands or contracts depending on the pressure change.

The movement of the bellows will be directly transferred to the spring, which will open or close the main valve, thus keeping the downstream pressure at a certain level.

Suitable for small processes such as sewing, cleaning, food industry, dyeing industry, apparel industry, heating equipment, sterilizer, rubber vulcanizer, medical equipment, bio-related equipment.

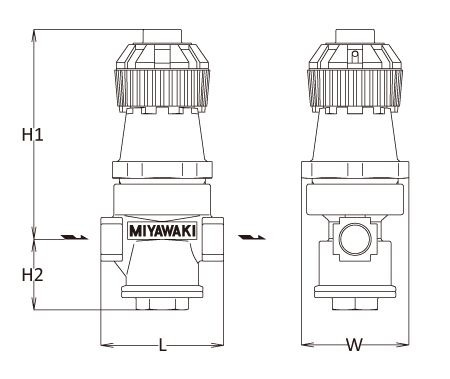

Compact and lightweight design allows installation in tight spaces.

(Model RE2 is the world's smallest steam pressure reducing valve)

- Max. Operating Pressure

- 1,6MPa

- Max. Operating Temperature

- 204℃