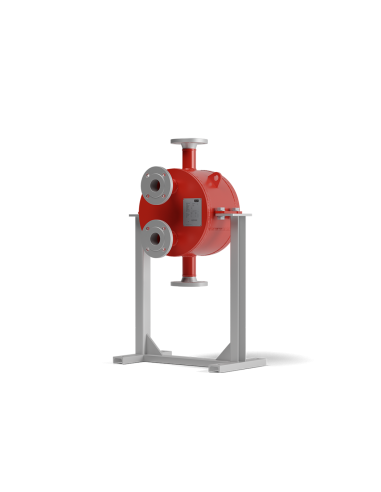

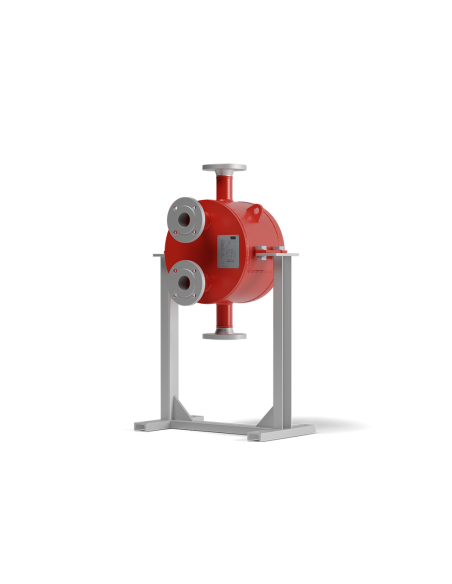

Plate & shell heat exchangers by Sondex/Danfoss are advanced thermal solutions designed to efficiently transfer heat between two fluids. These exchangers combine the benefits of plate heat exchangers and shell-and-tube heat exchangers, offering a compact design with high thermal efficiency and robust performance. They are ideal for applications requiring high pressure and temperature resistance, providing reliable operation in demanding industrial environments. The design ensures easy maintenance and cleaning, making them a cost-effective choice for various industries, including chemical processing, power generation, and HVAC systems.