ARI-CHECKO®-V Check Valves:

-

Types:

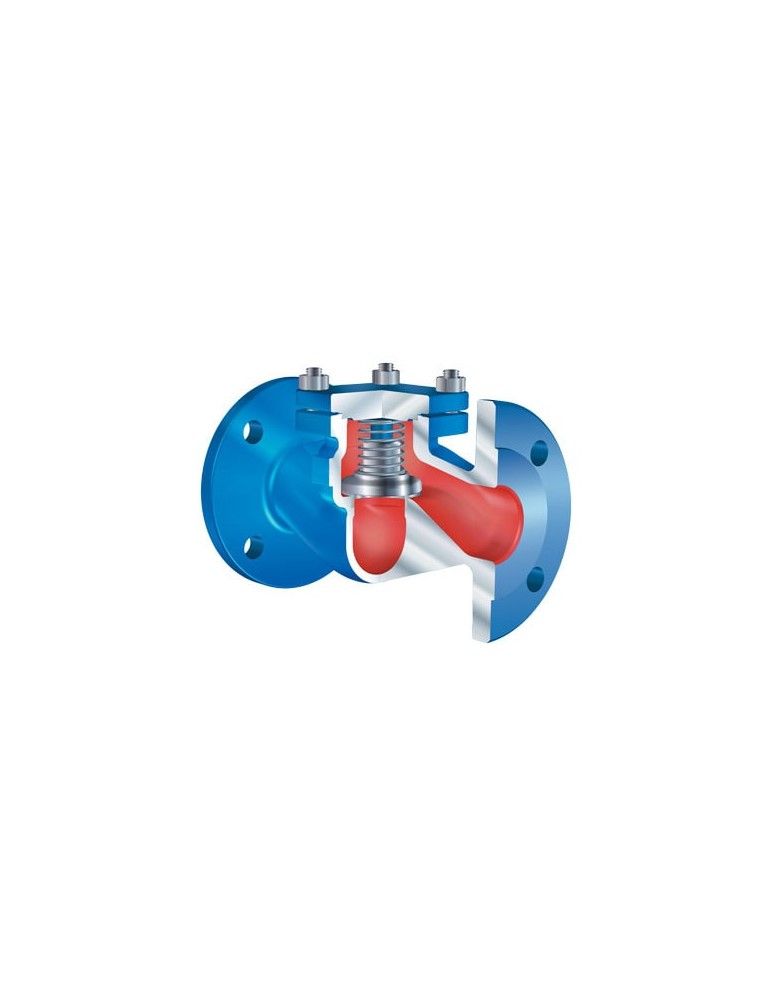

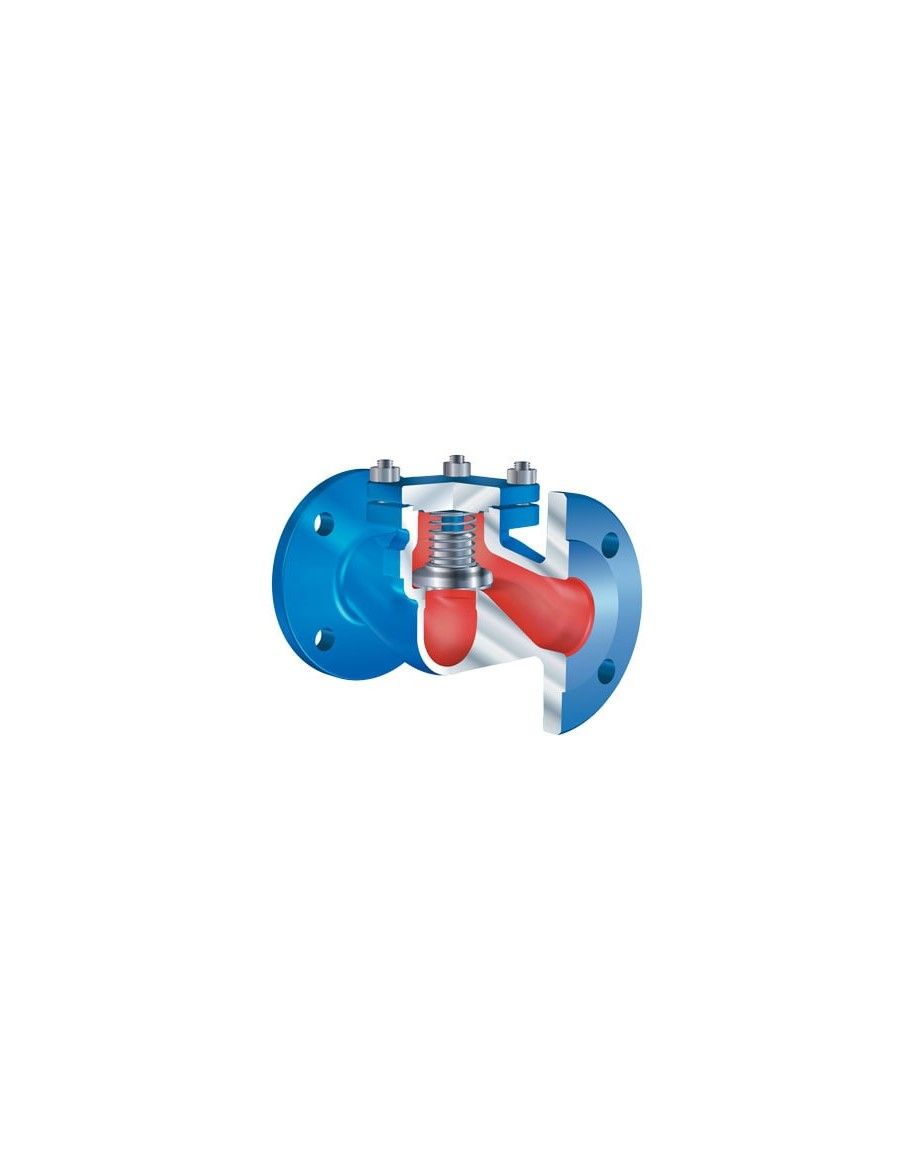

- Straight-through with flanges (grey cast iron, SG iron, cast steel, forged steel, stainless steel).

- Angle pattern with flanges (various materials).

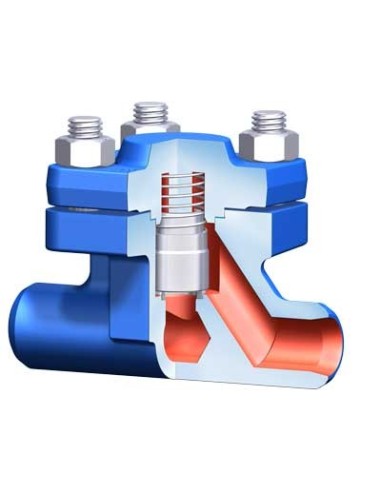

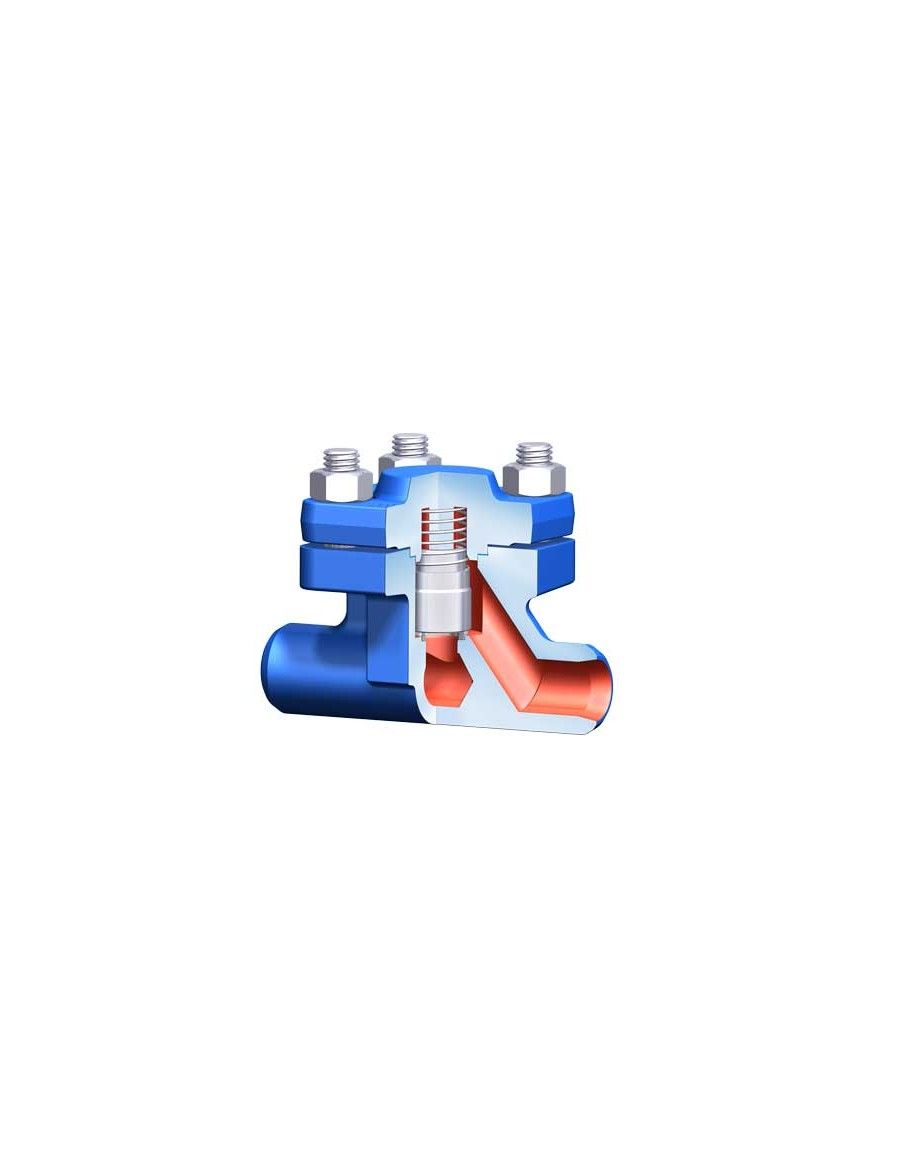

- Straight-through with butt weld ends (forged steel, cast steel).

- Y-pattern with flanges (stainless steel).

- Y-pattern with butt weld ends (cast steel).

-

Materials:

- Grey cast iron (EN-JL1040), SG iron, cast steel, stainless steel (1.4408), and forged steel.

- Seat rings made of stainless steel or copper-based materials for specific sizes.

- Springs and other components made of high-quality stainless steel (X10CrNi18-8).

-

Pressure Rating:

- Available with PN6, PN16, PN25, and PN40 pressure ratings.

-

Sealing Options:

- Metallic sealing (standard).

- PTFE-soft sealing for improved leak prevention.

-

Applications:

- Suitable for systems with high flow turbulences, pressure reduction stations, and compact plants.

- Recommended when there is no flow stabilizing pipe dimension or when a large valve diameter is selected.

-

Installation:

- Options for flanged ends or butt weld ends as per DIN EN 12627.