This type of steam trap utilizes the difference in density between steam and condensate, and uses the buoyancy of an open float that takes the form of a bucket to open and close a valve. Miyawaki inverted steam traps include the low-discharge ES Series and the high-discharge ER Series. Both the series use Miyawaki’s SCCV System* for the valve, which offers superb durability and valve closing performance. In addition, ER Series products use a differential pressure double valve system to achieve high discharge, which allows them to discharge the same volume while being much smaller in comparison to other companies’ inverted bucket traps.

*SCCV (Self Closing and Centering Valve) System

The valve holder is held in place by a lever, and the valve itself is placed in the small space inside the holder where it is free to move. This design moderates the mechanical force to which is transferred via the lever.

- Max. Operating Pressure

- 1,6MPa

- Max. Operating Temperature

- 300℃

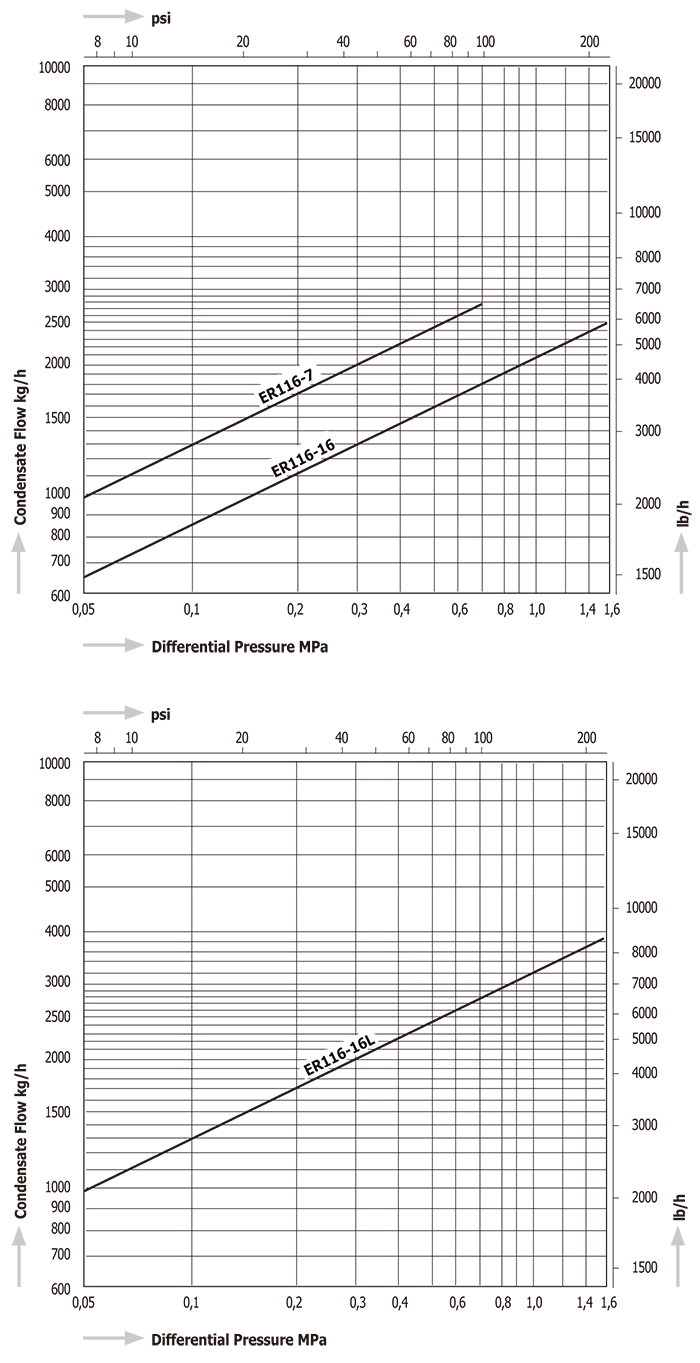

- Max. Discharge Capacity

- 3,95t/h