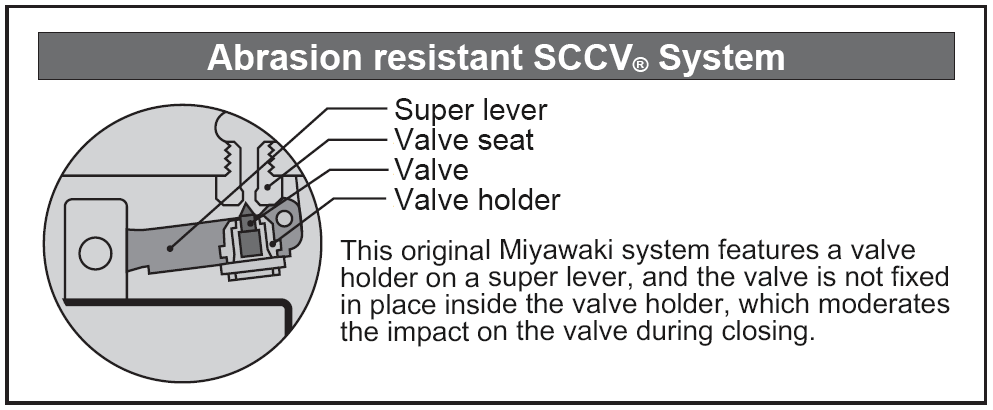

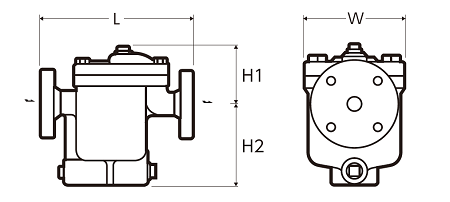

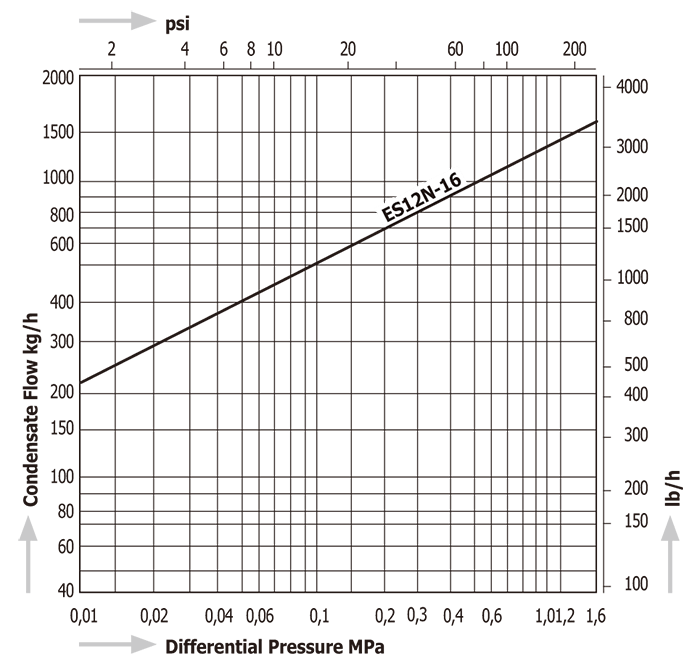

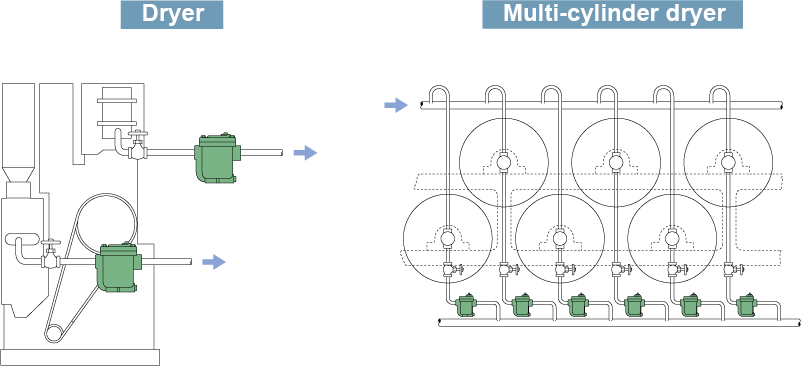

The Inverted Bucket Steam Trap ES12N by Miyawaki is a reliable and efficient steam trap designed for industrial applications. It operates on the inverted bucket principle, which ensures effective condensate removal while minimizing steam loss. The ES12N is known for its durability and robust construction, making it suitable for high-pressure and high-temperature environments. Its design allows for easy maintenance and long service life, providing consistent performance in steam systems. Ideal for use in various industries, the ES12N helps optimize energy efficiency and maintain system reliability.