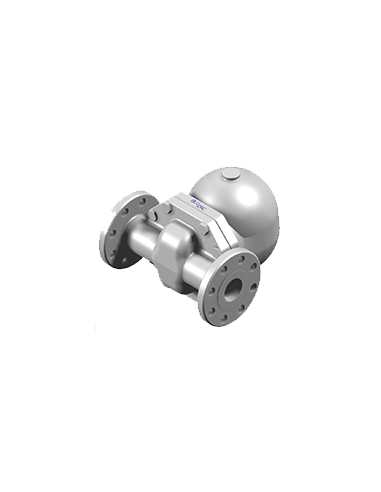

The Ball float type of steam trap is created for standard and special applications, designed to the customer’s specifications, welded body. Steam traps suitable for high capacities at low pressure, usable for all applications.

How it works:

- The Ball is placed on the base, the shutter is closed; in the steam trap there is no fluid of any kind.

- Start-up: when the condensate begins to circulate, the ball start floating and the steam trap eliminates the excess condensate.

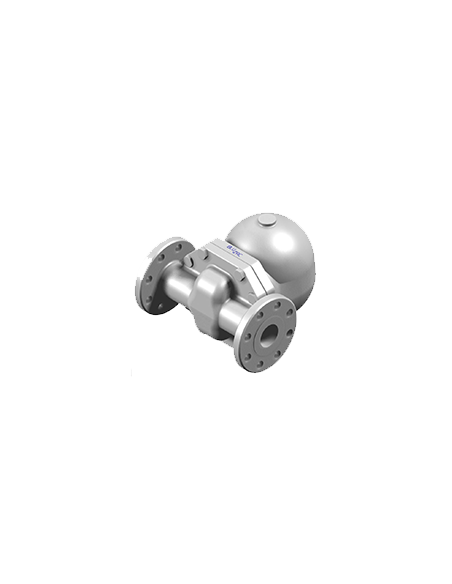

| SIZES |

|---|

| from ½” to 2” |

| CONNECTIONS | ||

|---|---|---|

| Flanged | FLG | ANSI B16.5 |

| Screwed | NPT BSP |

ANSI B1.20.1 ANSI BS21 |