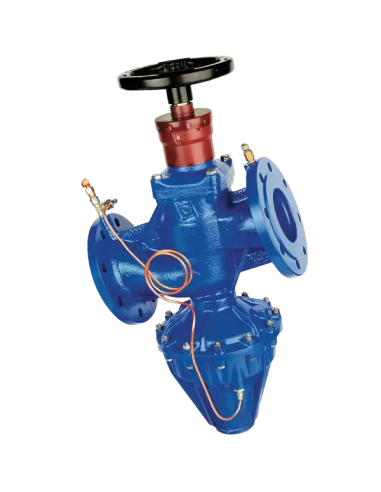

MODULATING DIFFERENTIAL PRESSURE CONTROL, SHUT-OFFAND FLOW RATE MEASUREMENT VALVE

The modulating valves in series EKOFLUX.M balance and control the differential pressure (DPCV) automatically and proportionally.

The valve balances the flow in the main network or in the single risers and branches of a heating/conditioning system, controls and keeps the differential pressure over the load at a stable value, reducing the risk of noisiness and wear of the thermostatic control valves.

Moreover, correcting the imbalances of the supply between the user units assures a better environmental comfort together with an optimization of the energy consumption.

The regulation range of the differential pressure delivered is comprised between

0.2 - 0.8 and 1 - 1.6 bar for DN65-100 and between 0.2 and 1 bar for DN125-150.

The valves perform shut-off and measuring functions.

Advantages: they allow reducing purchase costs, and installation and set-up times.

No need for an external energy supply.

Accessories

- Electronic instrument for measuring the differential pressure, flow rate and balancing of the circuit

- Pressure gauge probe adaptor

- Fitting, adapter, compression fitting, copper capillary pipe, test plug.