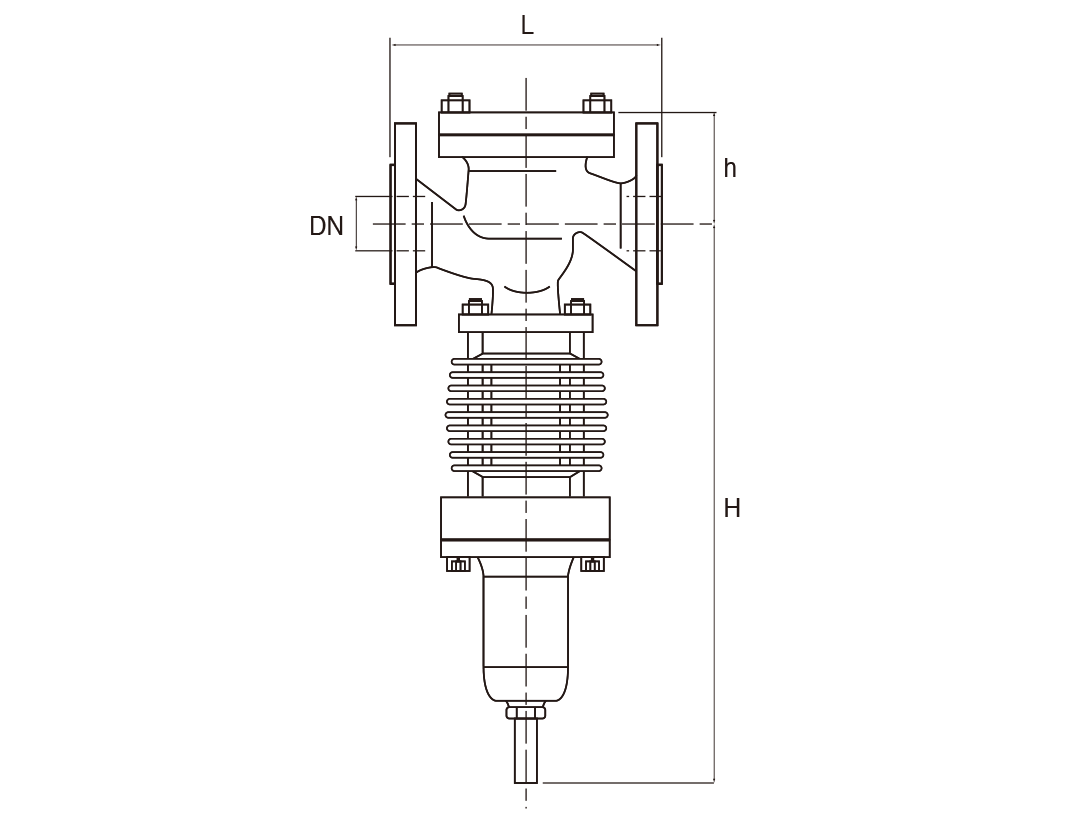

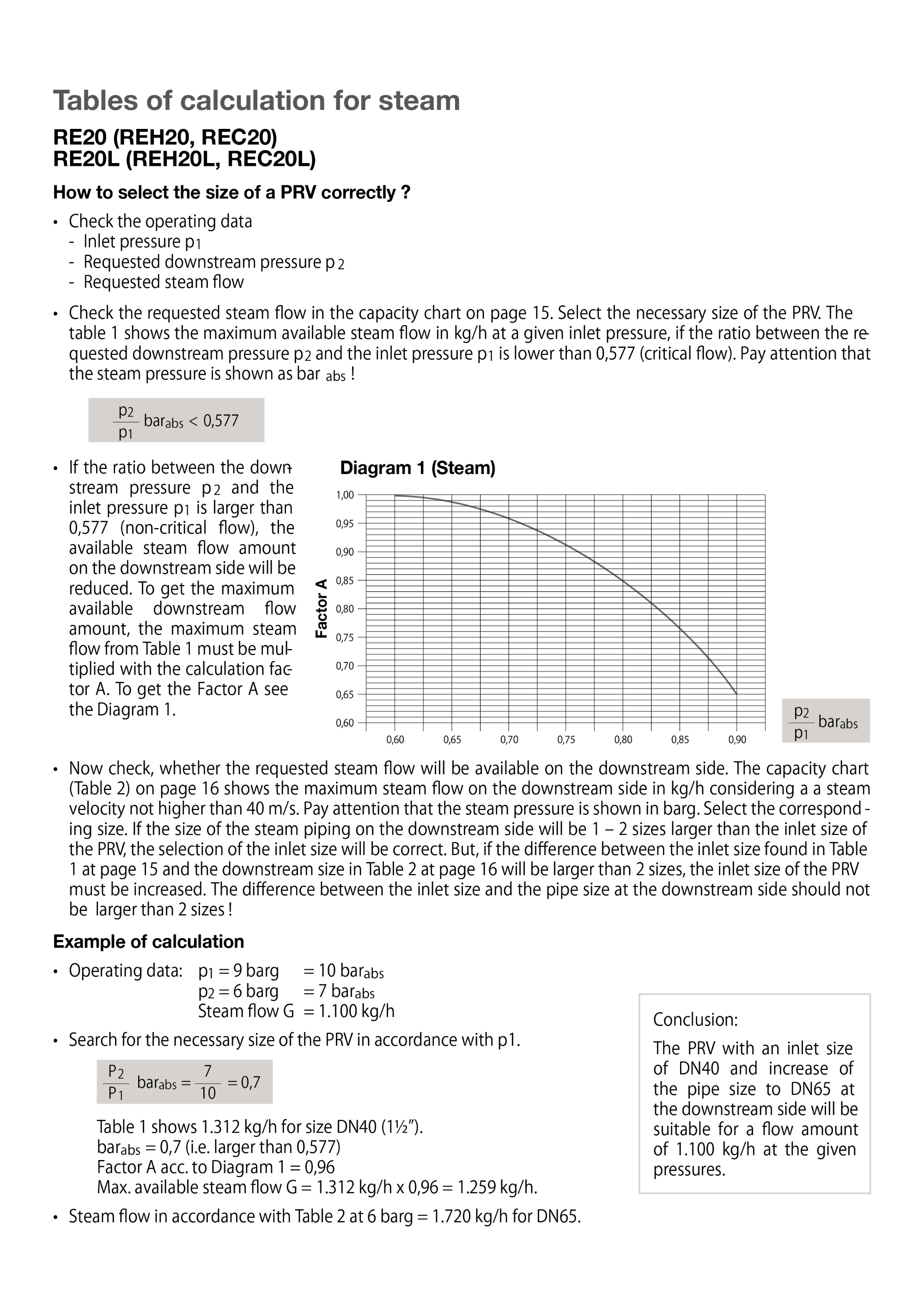

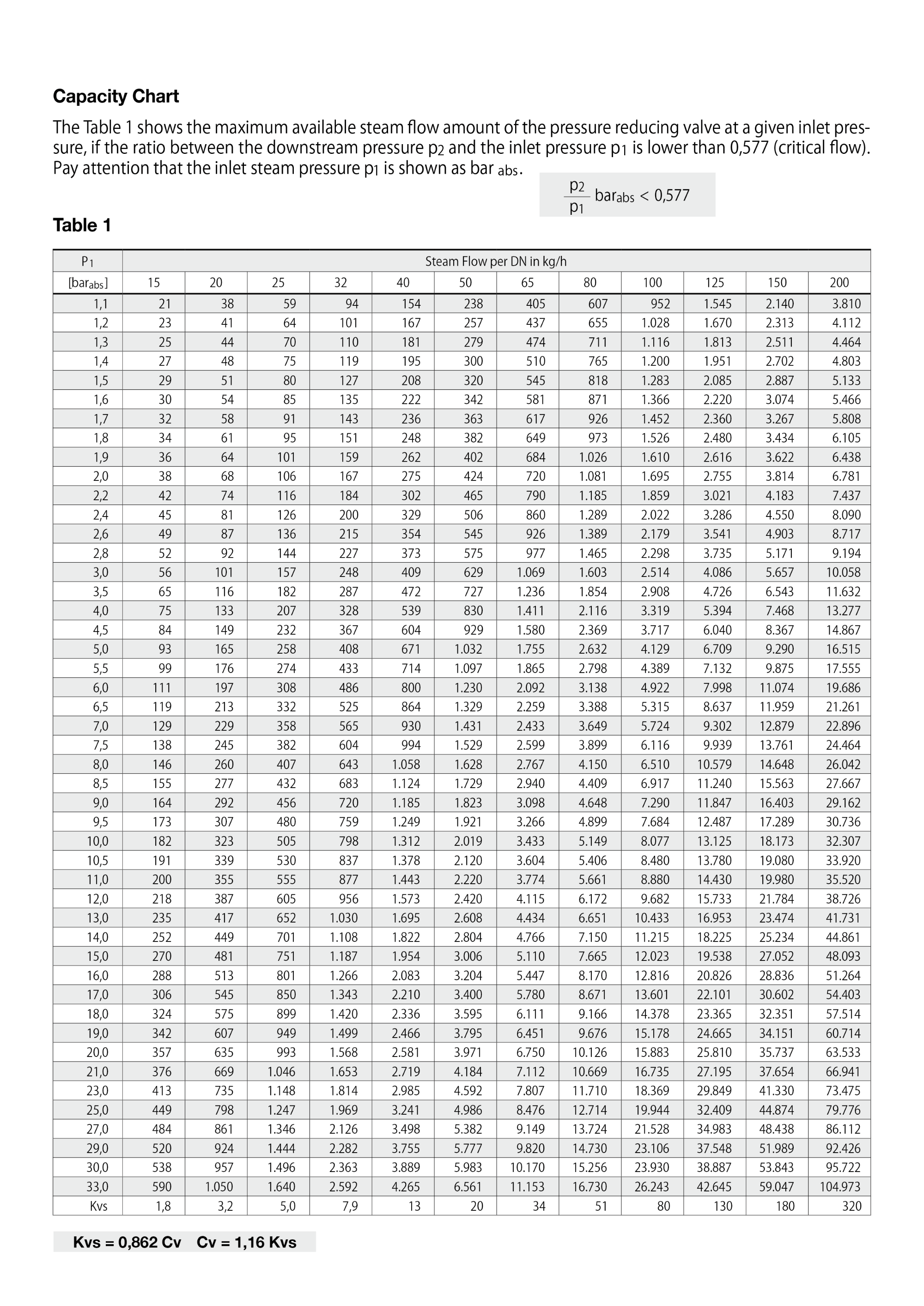

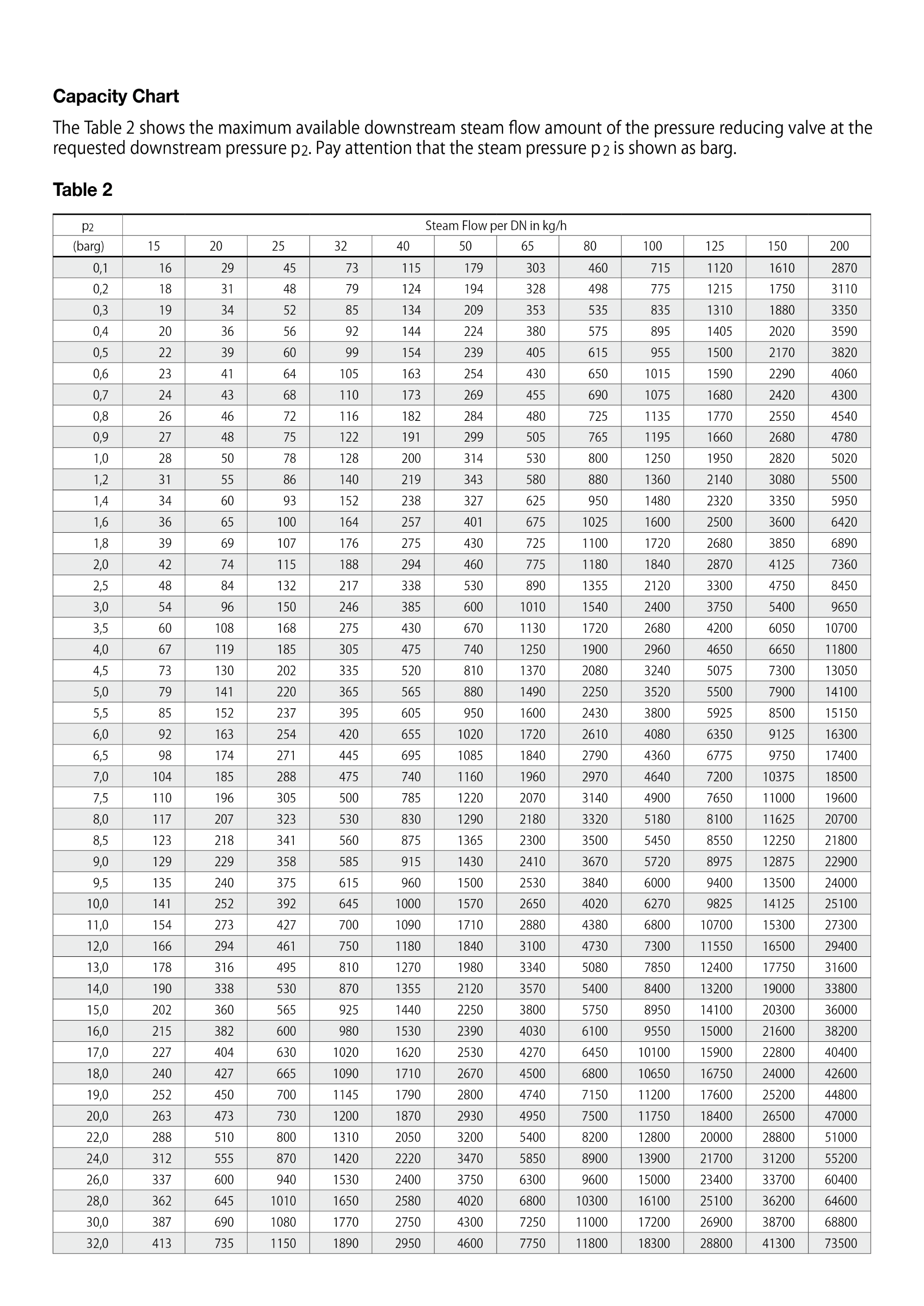

The REC20 by Miyawaki is a direct-acting pressure reducing valve specifically designed for steam applications. This valve efficiently regulates and reduces steam pressure to a desired set level, ensuring optimal performance and safety in steam systems. Its direct-acting mechanism allows for precise control and quick response to pressure changes, making it ideal for various industrial applications. The REC20 is known for its reliability, durability, and ease of maintenance, making it a preferred choice for engineers and technicians working with steam systems.