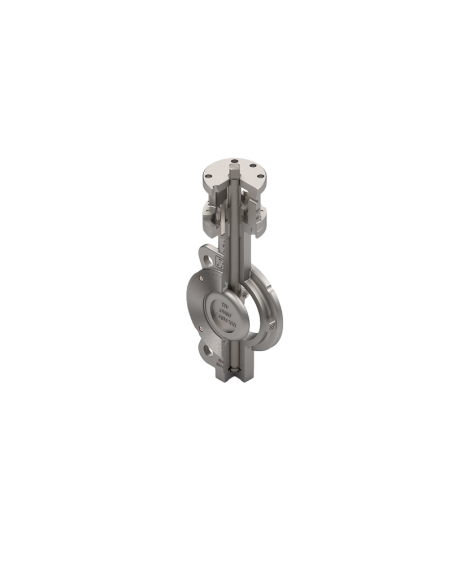

Manufacturing range: DN32 - DN600

Distance between flanges: EN 558 Series 20, Serie 13 - ISO 5752 Series 20, Serie 13 - API 609, EN 593, - BS 5155, MSS-SP-68

Installation between flanges: PN10/16/25/40 - ANSI150 Lbs./300 Lbs.

Flanges: ISO 7005, DIN 2501, BS-4504, ANSI Class 150: ANSI B16.5

Upper flange connection: ISO 5211

Tests: API 598, ANSI/ASME B16.34, BS1560, EN593

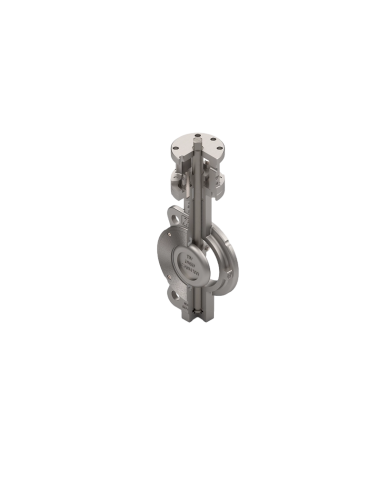

Coating: Stainless steel

Work Pressure: DN32 - DN600, Max. 25 bar.

Properties

- Double axis displacement.

- Longer useful life, minimal friction between the disc and the seat.

- Complete tightness. Class VI - ISO 5208 (Rate A)

- Self-sealing mechanism that guarantees a tight seal and low torque.

- Offset axle allows for easy seat replacement.

- Quick on-site maintenance.

- High performance.

- Low cost.

- Light weight.

- Same construction, three types of seat: 100% PTFE / R-PTFE, INCONEL, Fire Safe.

- Stainless steel butterfly.

- Stainless steel shaft.

- Possibility of operation with different controls (lever control, reducer, pneumatic, electric, hydraulic actuator...)

- Standard and threaded retainer.

- Valve construction with vacuum-safe R-PTFE seal.

- TA-LUFT VD 2440 ISO 15848 design.

- PED 2014/68.

- ATEX 2014/34/EU - ATEX II 2GDc.

- SIL IFC 61508.

General applications

- Vacuum services

- Chemicals

- petroleum products

- Ethylene

- LPG/LNG

- Hydrocarbon derivatives

- Steam

- Air

- Seawater

- saturated water

- saturated steam

- Heat-insulated gases

- Bitumen / Asphalt

- Corrosive liquids

- thermal oil

- Cogeneration

- Fire installations

- Abrasives

- Sludge