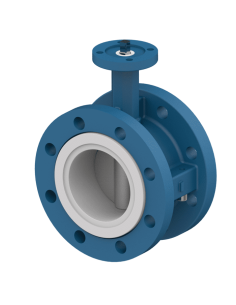

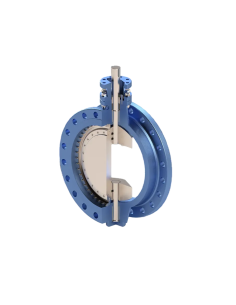

Flanged

Butterfly valve JIS Short Double Flanged - S36 | Alfa Europe

Double Flanged

5K

10K

JIS

EN-JS 1030 (GGG40) Ductile Iron

1.4408

ASTM A216 WCB

BS 1400 AB2 (Aluminium Bronze)

EPDM

FKM (Viton®)

NBR

Silicone