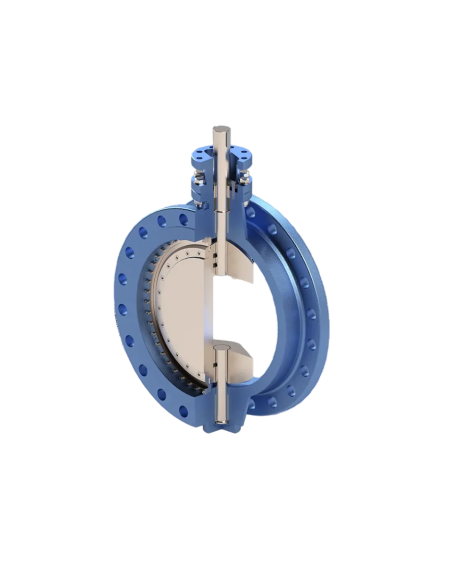

Manufacturing range: DN50 - DN1600 (larger diameters available on request)

Distance between flanges: API 609 - ISO 5752 - BS 5155

Installation between flanges: PN10/16/25 - ANSI150 Lbs./300 Lbs./600 Lbs.

Flanged: ISO 7005-1/2 - DIN 2501 PN10/16/25/40 - ASME B16.5 (150-300Lbs) - ASME B16.47 Series A/B (150-300Lbs) - ASME B16.1 Class 125/250 Lbs - AWWA C20

Upper flange connection: ISO 5211

Tests: ISO 5208, API598, EN 12266, ANSI/ASME B16.34, BS 1560, EN 593

Coating: Rilsan® / Inox

Work Pressure: up to 100 bar

Properties

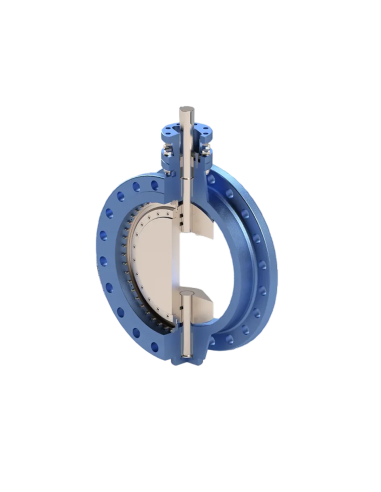

- Triple axis offset.

- Longer useful life, minimal friction between the disc and the seat.

- Complete tightness. Class VI - ISO 5208 (Rate A)

- Self-sealing mechanism that guarantees a tight seal and low torque.

- Offset axle allows for easy seat replacement.

- The disc seat can be easily replaced without the need for special tools.

- Quick on-site maintenance.

- High performance.

- Locking device on the lower shaft on request.

- Design suitable for high pressures.

- Possibility of operation with different controls (lever control, reducer,

- pneumatic, electric, hydraulic actuator...)

- Bidirectional design on request.

- PED 2014/68.

- ATEX 2014/34/EU - ATEX II 2GDc.

- SIL IFC 61508.

- TA-LUFT VD 2440 ISO 15848 design.

General applications

- Sweet water

- Seawater

- Hot water

- Air

- Compressed air

- Feeding

- Vegetable fats and minerals

- Oils

- Refrigeration

- Ozone

- Nitrogen derivatives

- weak acids

- Concentrated and hot acids

- Chemicals

- Solvents

- Hydrocarbons

- Gases

- High temperature gases