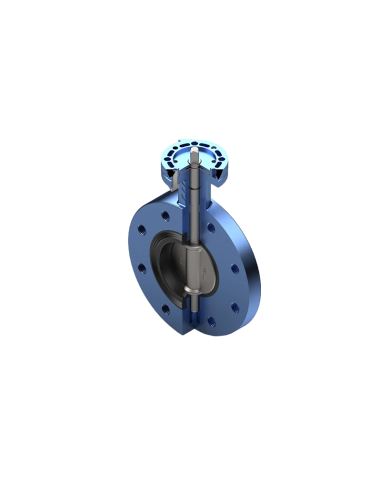

Manufacturing range: DN32 - DN2000

Distance between flanges: EN 558 Series 20 - ISO 5752 Series 20 - API 608 Table 1 - B5 5155 Series 4

Installation between flanges: PN10/16-ANSI150 Lbs.

Flanged: ISO 7005, DIN 2501, BS-4504, ANSI Class 150: ANSI B16.5

Upper flange connection: ISO 5211

Tests: ISO 5208, zero leakage API 598

Coating: Rilsan®

Working pressure: DN32 - DN600, Max. 20 bar > DN600, Max. 16 bar

Properties

- Certified and approved valves for various applications.

- Zero leakage.

- Replaceable or vulcanised seat.

- Single-piece shaft, complete protection of shaft and body against circulating liquids.

- Bidirectional flow.

- Self-cleaning.

- Light-weight design, easy to install

- Easy to maintain

- Possibility of operation with different controls (lever control, reducer, pneumatic, electric, hydraulic actuator...)

- Low operating torque.

- Aerodynamically designed disc for minimising pressure loss.

General applications

Water:

- Irrigation

- Potable water

- Seawater

- Water supply

- Gasoline

- Industrial water

- Residual water

- Fire protection systems

- Cooling towers

Industry:

- Food

- Paper

- Chemicals

- Petrochemicals

- Engineering

- Cement

- Petroleum

- Metalworking

- Energy Generation

- Naval Building

- Mining

- Heating

- Air-conditioning

- Compressed Air

- Construction