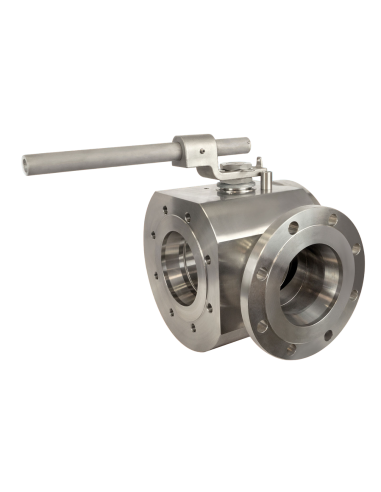

Three way 90° ball valve “wafer type”, full bore ISO 14313, made from round bar, according EN 12516.2; ASME B16.34; ISO 14313; EN 1092-1; ASME B16.5.

Available size from DN 15 to DN 150 in carbon steel, stainless steel and special steel

Rating PN 10÷40 / ANSI 150 (On request available ANSI 300/600).

With “L” bore ball type.

Chevron ring on stem.

On request:

– with o’ring on stem (patent n°00219688).

– fire-safe execution according to ISO 10497 API 607

– fire-safe execution according to BS6755 API 607/6FA (patent n° 00219617).

– according to PED 14/68/UE directive

– according to TPED 2010/35/UE directive

– according to ATEX 14/34/UE directive

– degreased according to ISO 23208 for oxigen serivce

– certified in safety system S.I.L. 3.

– certified for fugitive emission in class “A” ISO 15848.

Standard productions

anti blow out proof stem

construction and marking BS 5351

carbon steel valves painted with first coat of epoxy-polyammidic RAL 5012 35 microns

antistatic device

top flange ISO 5211

all valves 100% air tested under water at 100 psi

On demand accessories

PTFE seats filled glass – carbon – S.S. – bronze, metal core

cryogenic valves

stem extention

oval handle

pneumatic actuator double/single acting

electric motor

manual gear box

electric-pneumatic limit switches/solenoid valves