CHECK VALVES MANUFACTURER

WATER TECHNOLOGIES – IN HOUSE MANUFACTURING

CASTFLOW VALVES S.L., is formed by technicians that have been developing valves for many years.

Counting on this experience we created new patterns for castings, including the improvements that

have been necessary to obtain a longer durability and better hydraulic features.

CASTFLOW VALVES S.L. is a ISO 9001:2015

ISO 14001:2015 – ANNEX III MODULE H approved company for design and production.

We produce valves based on our own design and we can offer to our clients all

TECHNICAL SUPPORT related to our valves.

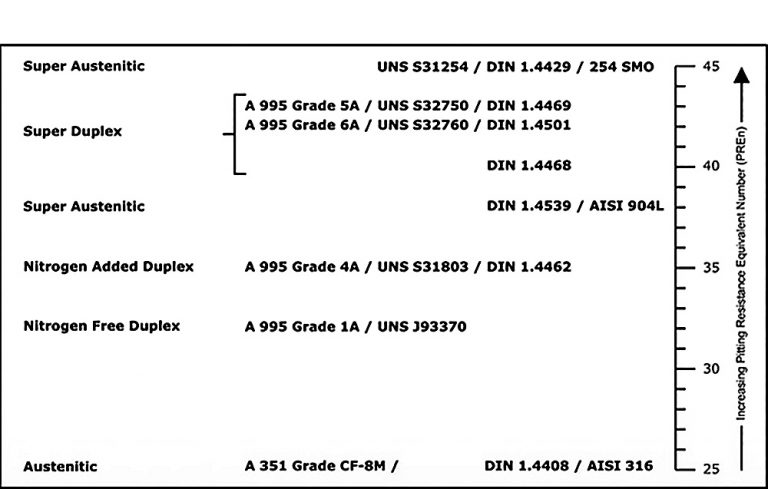

We require maximum quality on prime materials. The foundries we work with, are highly specialised in

materials and posses a very important knowledge in casting our products. Our department for investigation and development is orientated to the technical requests of

our customers, adapting our development to these requests. The structure of CASTFLOW VALVES S.L.is oriented to serve our customers technical requests.

ISO 9001:2015

ISO 14001:2015

ANNEX III MODULE H

- CERTIFICATE OF THE QUALITY ASSURANCE SYSTEM EUROPEAN DIRECTIVE 2014/68/EU

- ISO 14001:2015

- ISO 9001:2015

Quality assurance plans

PROVIDING HIGH QUALITY PRODUCTS

Based on the customers requirements CASTFLOW VALVES S.L. can proceed with testing methods

according to a quality assurance plan and test and inspection schedules.

Receiving inspection

In process Control

Non destructive testing

US-testing-magetic

particle-dye

penetrant tests Porotest Dk30

Output control

pressure test of each valve

output documents

termination control

marking and packaging control